I. Solution Overview

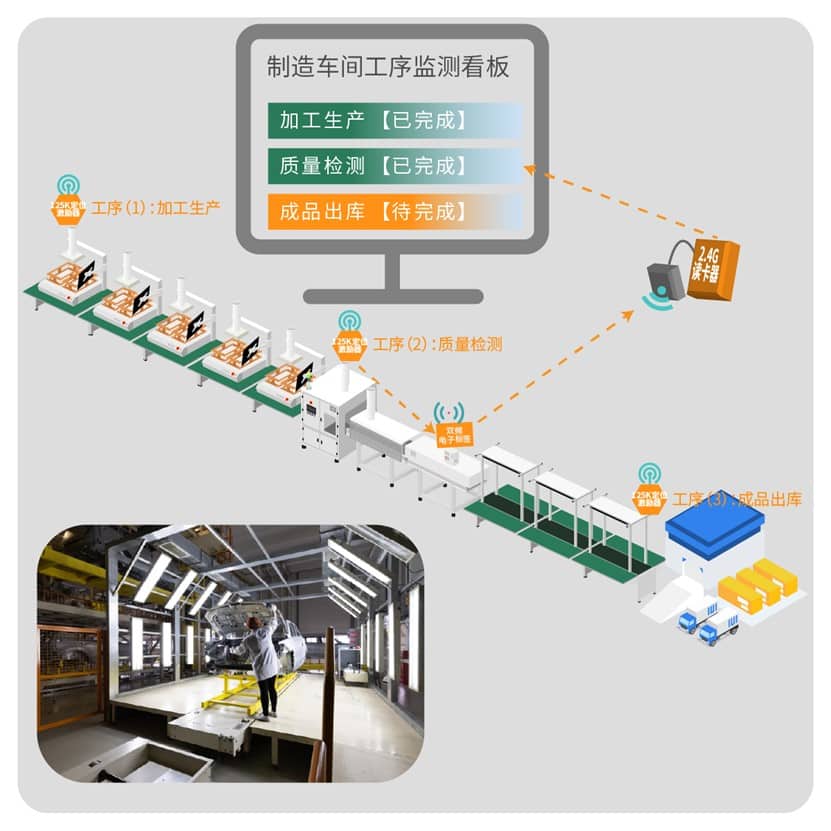

As competition in the manufacturing industry intensifies and market demands constantly evolve, workshop production progress and process monitoring have become crucial for manufacturing enterprises to enhance production efficiency, reduce costs, and enable timely decision-making. In this context, the Workshop Production Progress and Process Monitoring module of the Manufacturing Execution System (MES) has emerged. By deploying ZigBee dual-frequency tags on workshop materials, equipment, and personnel, and utilizing ZigBee dual-frequency locators and card reader base stations to collect data integrated with the MES system, it achieves precise monitoring of production progress and processes.

II. Specific Implementation

- Tag Deployment

- Material Tags: Attach a unique ZigBee dual-frequency tag to each raw material and semi-finished product. The tag ID is bound in the software to information such as material number and batch.

- Equipment Tags: Install ZigBee dual-frequency tags on production equipment. The tag ID is bound in the software to information such as equipment number and maintenance details.

- Personnel Tags: Employees wear ZigBee dual-frequency badges. The tag ID is bound in the software to personal identity information.

- Dual-Frequency Reader Installation

- Install ZigBee dual-frequency locators and readers at key locations such as workshop entrances, process handover points, and warehouse entrances/exits.

- For example, readers at process handover points can automatically identify the arrival and departure of materials, triggering process transition records.

- MES System Integration

- Data Transmission: Transmit data collected by ZigBee dual-frequency readers to the MES system in real-time.

- Process Monitoring: The MES system determines the start, progress, and end times of processes based on material flow and equipment usage. For instance, when an item with a specific material tag arrives at a workstation for a particular process and the corresponding equipment starts operating, the MES system records the process start; when the material leaves the area, the MES system records the process end.

- Production Progress Calculation: The MES system calculates overall production progress based on process completion. For example, if a product has 10 processes and 6 are completed, the production progress is 60%.

- Exception Handling

- If materials remain at a process for an excessively long time, the MES system triggers an alarm.

- In case of equipment failure, by associating personnel badges with equipment tags, the system can quickly identify the employee operating at the time, facilitating traceability and problem resolution.

III. Benefit Analysis

- Improve Production Efficiency: Precise process monitoring reduces waiting time between processes, enhancing overall production efficiency.

- Quality Traceability: Facilitates tracing the production status of products at each process, aiding quality control.

- Real-time Monitoring: Management can understand production progress in real-time, enabling timely decision-making and adjustments.

The Workshop Production Progress Monitoring MES system plays a pivotal role in modern manufacturing. Through real-time monitoring, scheduling, and data analysis, it enhances production efficiency, resource utilization, and product quality. By effectively managing and optimizing production processes, enterprises can achieve higher production efficiency, faster delivery cycles, and greater customer satisfaction. Therefore, the Workshop Production Progress Monitoring MES system is one of the essential tools for manufacturing enterprises to realize smart manufacturing and enhance competitiveness.

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier