I. Transformation and Challenges for Manufacturing Enterprises

With the advancement of Industry 4.0, manufacturing enterprises are facing numerous challenges. Issues such as rising labor costs, inventory management, and worker shortages are becoming increasingly prominent. In the process of automation and intelligentization, while integrated solutions are widely adopted, there may exist underlying blind spots and diminishing returns. For instance, in the context of Industry 4.0, integrated design and manufacturing solutions attempt to break down inter-enterprise barriers through the internet to achieve collaborative development of the industrial chain. However, in practice, operational disruptions and high costs may arise due to various factors. Industry 4.0 aims to achieve the digital transformation of manufacturing through intelligent means, with its core lying in applying technologies like the Internet of Things (IoT), big data, and artificial intelligence to production processes. Yet, many manufacturing enterprises, while striving to build smart factories, often lack systematic and comprehensive intelligent transformation of core production lines and heavy machinery. On one hand, enterprises are shifting from internal integration to industrial chain collaboration, adopting models like integrated design and manufacturing solutions involving outsourcing of component design or entire vehicle design, which also brings challenges in resource integration and management. On the other hand, traditional production and operation models face difficulties such as a sharp decline in labor force, increased labor costs, insufficient capacity, low efficiency, and inconsistent processing quality when confronting the economic "new normal." For example, some enterprises remain labor-intensive, with high management costs, low production efficiency, and product quality dependent on workers' technical skills, leading to uneven quality. In this context, Real-Time Location System (RTLS) technology has garnered significant attention as a cost-effective and minimally disruptive solution. It can provide manufacturing enterprises with more granular indoor location data, accurate to the centimeter level, tracking production processes, material flow, or finished goods transfer. By understanding the location of all key components at any given time, it helps enterprises identify bottlenecks, improve production efficiency, and enhance management levels.II. Overview of RTLS Systems

2.1 What is an RTLS System

A Real-Time Location System (RTLS) is a system that utilizes advanced sensor technology and positioning algorithms to monitor and track the location of objects in real-time. It primarily consists of tags, readers/receivers, a backend system, and a user interface. Typically referring to a local positioning system, it can display the content, location, and time within a defined area, quantifying this data in a way understandable to the user. For example, in a manufacturing workshop, RTLS can show which order passed through which production area at a specified time, or which transportable container was loaded onto which truck during working hours. An RTLS system usually includes a series of reader antennas and base stations deployed on walls or ceilings within the monitored area. As assets or personnel move, the system captures location information from their attached electronic tags, generates real-time location data for the tags, and can also provide historical movement readings, including the number of times passing specific points and dwell time data.2.2 West-HN's ZigBee Indoor Positioning Technology

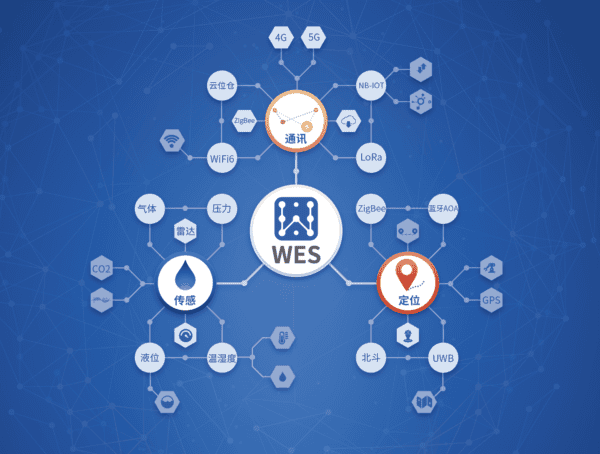

West-HN provides a powerful indoor positioning solution for manufacturing enterprises based on ZigBee technology. ZigBee is a low-power, low-data-rate wireless communication technology characterized by large network scale, self-organizing networks, low cost, high reliability, and strong security. West-HN's ZigBee indoor positioning technology can provide manufacturing enterprises with indoor search, positioning, and inventory solutions, along with various audible and visual electronic tags. Through a "Lego-style" production model, West-HN can meet the diverse needs of the Industrial Internet of Things (IIoT) industry, with wide applications across multiple fields. In manufacturing enterprises, West-HN's ZigBee indoor positioning technology enables more efficient and accurate inventory management, improves production efficiency, optimizes processes, enhances workshop safety management, and provides enterprises with newer and more comprehensive business intelligence. For example, by tracking work-in-progress (WIP), finished goods, and raw materials in real-time, enterprises can precisely grasp material flow, optimize production layout, reduce inventory backlog, and improve asset utilization. Simultaneously, West-HN's ZigBee indoor positioning technology can integrate with other enterprise management systems to achieve intelligent production management. In summary, West-HN's ZigBee indoor positioning technology offers manufacturing enterprises an efficient, reliable, and low-cost real-time positioning solution, assisting them in achieving intelligent transformation and enhancing competitiveness.III. Benefits of RTLS Systems

3.1 Efficient Inventory Management

Efficient inventory management is crucial for manufacturing enterprises. Real-Time Location Systems (RTLS) offer numerous benefits, helping enterprises locate lost inventory, reduce search time and unnecessary replacements, improve efficiency and productivity, and lower operational costs. Firstly, RTLS provides the capability for automated inventory reporting. Inventory no longer requires scheduled downtime to check critical tools, search for missing items, or individually rescan materials that haven't moved. Instead, it becomes an autonomous, always-up-to-date process. Inventory managers can also create custom alerts when items leave their permitted zones, quantities are low, or other performance parameters are met. Secondly, RTLS can reduce paperwork in the checkout process. In environments like factories where thousands of parts move daily, checking tools or leased equipment in and out can be a headache. Automating these processes with RTLS, such as knowing where workers are and where key items belong, can simplify the checkout process to a single step: picking up the required item. Furthermore, RTLS enables quick location of lost items. When an item isn't where it should be, factory workers don't need to go to the shop floor to start searching. They can simply enter identification information on a mobile device to see a current picture of where that asset is now. Some wayfinding RTLS solutions even provide a path from the worker's current location to the needed item. Additionally, RTLS can generate usage data. Lost items are less likely to be used, and items in their normal spots might also be idle. Real-time location data provides a simple way to study the usage and demand for vehicles, machines, tools, and even individual workstations, helping identify equipment shortages or backlogs in other areas, translating into higher productivity and increased revenue where more items need to be procured. Finally, RTLS can enhance other technologies and existing workflows. It is not meant to eliminate the carefully designed ways manufacturers already operate but can be used to inform, study, evaluate, or update almost any work involving location, from assembly line processes to quality control, to loading and delivery. West-HN's ZigBee indoor positioning technology excels in inventory management. By tracking raw materials, parts, tools, and inventory in real-time, enterprises can precisely grasp material flow, optimize production layout, reduce inventory backlog, and improve asset utilization.3.2 Enhancing Manufacturing Process Efficiency

RTLS also plays a significant role in enhancing manufacturing process efficiency. This includes tracking work-in-progress (WIP), locating machines, and identifying bottlenecks to optimize production flow. In the manufacturing process, RTLS can collect and transmit time and motion data. Enterprises can obtain data on how objects actually move and analyze the patterns behind these moving parts. Real-time location data can show which spaces can be optimized, movement history can reveal anomalies in normal production processes, and timing data can quantify the time required for each production stage. RTLS can also provide early warning signals, enhancing asset visibility and allowing problems to be identified in advance. If a critical piece of equipment hasn't changed location for an extended period, it might indicate a malfunction. The system can issue timely alerts for maintenance personnel to address it, preventing impacts on production schedules. Location data can provide positive updates, such as marking an item's progress from assembly to quality control, or triggering status updates when a manufactured part moves from one step to another. Location-based WIP tracking provides a detailed real-time picture showing the progress and sequence of key processes, helping to reduce manual scans and the number of required procedures. RTLS systems can reduce errors through automatic real-time updates, rather than updating only upon scanning. In a manufacturing process with 30 steps, if manual scanning is used to record each step, a missing scan point could cause issues throughout the process if not immediately noticed by staff. With an RTLS system, all key location points between scans can be mapped, virtually eliminating the scans themselves, making the process more accurate, efficient, and agile. Bottlenecks and obstacles between the start and end of a project can cause significant losses. With an RTLS system, tracking area-level location data can show the time differences a project spends at various stations. More precise location data or tracking history can help accurately pinpoint where and when each delay began, allowing problem-solving plans to be based on real data, not just best guesses. West-HN's ZigBee indoor positioning technology can track WIP in real-time, helping enterprises quickly identify bottlenecks and issues, adjust production plans promptly, and avoid resource waste. Simultaneously, it can integrate with other enterprise management systems for intelligent production management.3.3 Improving Workshop Safety Management

RTLS systems can improve workshop safety management, protect worker safety, and provide new business intelligence for continuous improvement. In terms of worker safety, RTLS systems have various applications. For example, contact tracing can help identify who was in contact with whom in case of an infection issue. In the current work environment, especially in places like factories, personnel contact is crucial for epidemic prevention and control. Many contact tracing solutions are now applied in manufacturing enterprises, with the primary goal of quickly identifying contacts if an infection arises. Using RTLS for contact tracing has distinct advantages because real-time location data can show not only the time, location, and duration of any interaction but also the time individuals spent between these interactions.Collision prevention functionality can provide real-time data, combined with other safety measures, to reduce workplace injuries. Workplace accidents cause significant losses to factories annually, with collision accidents being a major contributor. Existing safety measures include bright signage, audible alarms for moving vehicles or personnel, indoor traffic lights, deployable safety buffers, extensive training, and personal protective equipment for individual workers. RTLS provides real-time data that can better inform the use of other safety measures. RTLS systems can also identify congested or hazardous areas to prevent collision accidents. Through real-time location data, congested or hazardous areas can be identified, and early warnings can be issued to prevent collisions. For example, in employee location tracking, by equipping each employee, contractor, or site visitor with a tag, their precise location can be identified in real-time. Geofencing functionality allows setting any number of virtual zones representing geographical boundaries, automatically triggering responses when a tracked tag enters or leaves a zone. West-HN's ZigBee indoor positioning technology can monitor personnel safety in real-time, ensuring employee activities in hazardous areas are restricted. Simultaneously, the system can provide real-time alarms to promptly address safety hazards, offering enterprises better safety management solutions.IV. Long-term Advantages of RTLS Systems

The long-term advantage of RTLS systems lies in continuously providing enterprises with precise location data, supporting their digital transformation and intelligent development. This is specifically manifested in the following aspects:

4.1 Improving Production Efficiency and Quality

In manufacturing enterprises, RTLS systems can track every link in the production line in real-time, helping managers quickly identify bottlenecks and issues, adjust production plans promptly, and avoid resource waste. For example, through real-time data, enterprises can accurately understand the location of WIP, optimize production layout, and improve production efficiency. Simultaneously, RTLS systems can provide early warning signals, enhancing asset visibility and allowing problems to be identified in advance. If a critical piece of equipment hasn't changed location for an extended period, it might indicate a malfunction. The system can issue timely alerts for maintenance personnel to address it, preventing impacts on production schedules. Furthermore, RTLS systems can integrate with other enterprise management systems to achieve intelligent production management. For instance, by analyzing real-time location data, production processes can be optimized, inventory management efficiency improved, and worker safety enhanced. West-HN's ZigBee indoor positioning technology excels in this regard, providing manufacturing enterprises with an efficient, reliable, and low-cost real-time positioning solution, assisting them in achieving intelligent transformation and enhancing competitiveness.4.2 Optimizing Inventory Management

Efficient inventory management is crucial for manufacturing enterprises. RTLS systems provide the capability for automated inventory reporting. Inventory no longer requires scheduled downtime to check critical tools, search for missing items, or individually rescan materials that haven't moved. Instead, it becomes an autonomous, always-up-to-date process. Inventory managers can also create custom alerts when items leave their permitted zones, quantities are low, or other performance parameters are met. RTLS systems can also reduce paperwork in the checkout process. In environments like factories where thousands of parts move daily, checking tools or leased equipment in and out can be a headache. Automating these processes with RTLS, such as knowing where workers are and where key items belong, can simplify the checkout process to a single step: picking up the required item. Additionally, RTLS systems enable quick location of lost items. When an item isn't where it should be, factory workers don't need to go to the shop floor to start searching. They can simply enter identification information on a mobile device to see a current picture of where that asset is now. Some wayfinding RTLS solutions even provide a path from the worker's current location to the needed item. RTLS systems can also generate usage data. Lost items are less likely to be used, and items in their normal spots might also be idle. Real-time location data provides a simple way to study the usage and demand for vehicles, machines, tools, and even individual workstations, helping identify equipment shortages or backlogs in other areas, translating into higher productivity and increased revenue where more items need to be procured. West-HN's ZigBee indoor positioning technology excels in inventory management. By tracking raw materials, parts, tools, and inventory in real-time, enterprises can precisely grasp material flow, optimize production layout, reduce inventory backlog, and improve asset utilization.4.3 Enhancing Workshop Safety Management

RTLS systems can improve workshop safety management, protect worker safety, and provide new business intelligence for continuous improvement. In terms of worker safety, RTLS systems have various applications. For example, contact tracing can help identify who was in contact with whom in case of an infection issue. In the current work environment, especially in places like factories, personnel contact is crucial for epidemic prevention and control. Many contact tracing solutions are now applied in manufacturing enterprises, with the primary goal of quickly identifying contacts if an infection arises. Using RTLS for contact tracing has distinct advantages because real-time location data can show not only the time, location, and duration of any interaction but also the time individuals spent between these interactions. Collision prevention functionality can provide real-time data, combined with other safety measures, to reduce workplace injuries. Workplace accidents cause significant losses to factories annually, with collision accidents being a major contributor. Existing safety measures include bright signage, audible alarms for moving vehicles or personnel, indoor traffic lights, deployable safety buffers, extensive training, and personal protective equipment for individual workers. RTLS provides real-time data that can better inform the use of other safety measures. RTLS systems can also identify congested or hazardous areas to prevent collision accidents. Through real-time location data, congested or hazardous areas can be identified, and early warnings can be issued to prevent collisions. For example, in employee location tracking, by equipping each employee, contractor, or site visitor with a tag, their precise location can be identified in real-time. Geofencing functionality allows setting any number of virtual zones representing geographical boundaries, automatically triggering responses when a tracked tag enters or leaves a zone. West-HN's ZigBee indoor positioning technology can monitor personnel safety in real-time, ensuring employee activities in hazardous areas are restricted. Simultaneously, the system can provide real-time alarms to promptly address safety hazards, offering enterprises better safety management solutions.4.4 Supporting Enterprise Digital Transformation

With the advancement of Industry 4.0, digital transformation has become an inevitable trend for enterprises. RTLS systems can provide enterprises with precise location data, supporting their digital transformation and intelligent development. For example, by analyzing real-time location data, production processes can be optimized, inventory management efficiency improved, and worker safety enhanced. Simultaneously, RTLS systems can integrate with other enterprise management systems to achieve intelligent production management. West-HN's ZigBee indoor positioning technology can provide manufacturing enterprises with indoor search, positioning, and inventory solutions, along with various audible and visual electronic tags. Through a "Lego-style" production model, West-HN can meet the diverse needs of the Industrial Internet of Things (IIoT) industry, with wide applications across multiple fields. In manufacturing enterprises, West-HN's ZigBee indoor positioning technology enables more efficient and accurate inventory management, improves production efficiency, optimizes processes, enhances workshop safety management, and provides enterprises with newer and more comprehensive business intelligence. In summary, the long-term advantage of RTLS systems lies in continuously providing enterprises with precise location data, supporting their digital transformation and intelligent development. West-HN's ZigBee indoor positioning technology offers manufacturing enterprises an efficient, reliable, and low-cost real-time positioning solution, assisting them in achieving intelligent transformation and enhancing competitiveness.V. Evaluation and Selection of RTLS Systems

Selecting a suitable RTLS system based on the specific needs and environment of the enterprise is crucial. West-HN's WES-RTLS system, with its flexibility and affordability, is an ideal choice for heavy industrial plants.5.1 Key Factors for Evaluating RTLS Systems

- Positioning Accuracy: Different application scenarios have varying requirements for positioning accuracy. For example, in scenarios requiring precise tracking of high-value assets, such as locating parts in an automotive manufacturing plant, high-accuracy positioning systems ensure accurate knowledge of each part's location, improving production efficiency and quality control. For scenarios with relatively lower accuracy requirements, such as general material management, slightly lower accuracy systems may suffice. West-HN's ZigBee indoor positioning technology can provide flexible accuracy options based on different scenario needs, meeting the diverse requirements of enterprises.

- Cost-effectiveness: When selecting an RTLS system, enterprises need to consider deployment costs, tag costs, and long-term operational costs. Some positioning technologies, like UWB, offer high accuracy but also have relatively high deployment and tag costs. In contrast, West-HN's ZigBee indoor positioning technology, with its low cost and high cost-performance ratio, provides an economical solution for enterprises. West-HN's products, through a "Lego-style" production model, meet the "small volume, high variety" customization needs of the IIoT industry, winning the trust of domestic and international clients with a "low inventory, high fulfillment rate" supply-demand relationship.

- Environmental Adaptability: Different industrial environments have different requirements for the environmental adaptability of RTLS systems. In complex environments like chemical plants, thermal power plants, and coal mines, with numerous devices, complex production sites, and hazardous sources, there are many interferences for positioning signals, making ordinary positioning technologies inadequate. West-HN's ZigBee indoor positioning technology, through careful design and optimization, can operate stably in various complex environments, demonstrating good environmental adaptability. For example, in environments with metal and other reflective surfaces, West-HN's technology can effectively mitigate multipath propagation effects, ensuring positioning accuracy and reliability.

- Ease of Scalability: As enterprises develop and business expands, RTLS systems need to have good scalability to easily adapt to new application needs and business growth. West-HN's WES-RTLS system is highly scalable, allowing users to add additional components at any time, up to company-wide infrastructure, without additional configuration costs. This enables enterprises to flexibly expand the system according to actual needs in future development, meeting evolving business requirements.

- Data Security: In industrial production, data security is paramount. RTLS systems involve large amounts of location data and production information. If this data is leaked or tampered with, it could cause significant losses to the enterprise. West-HN's ZigBee indoor positioning technology emphasizes data security, employing advanced encryption technologies and security mechanisms to ensure data confidentiality, integrity, and availability. Simultaneously, West-HN's system can integrate with other enterprise security systems to jointly build a secure and reliable industrial production environment.

5.2 Advantages of West-HN's WES-RTLS System

- Flexibility: West-HN's WES-RTLS system is highly flexible, adaptable to different industrial environments and application needs. Whether in large heavy industrial plants or small manufacturing workshops, West-HN's system can be customized for deployment based on actual conditions, meeting the personalized needs of enterprises. For example, in factories with limited space, West-HN's system can use compact, aesthetically pleasing multi-functional electronic tag reader base stations, combined with ZigBee audible/visual tags, to achieve rapid inventory, precise item location, or personnel counting. In large warehouses, West-HN's system can use devices like extended industrial I/O and industrial edge computing gateways to achieve real-time monitoring and management of inventory.

- Affordability: West-HN's WES-RTLS system offers a high cost-performance solution for enterprises with its affordable price. Compared to other high-end positioning technologies, West-HN's ZigBee indoor positioning technology significantly reduces system deployment and tag costs while ensuring positioning accuracy and functionality. This makes advanced real-time positioning systems accessible to more enterprises, enhancing their production efficiency and management levels. Simultaneously, West-HN's system features low power consumption and low operational costs, saving enterprises long-term operational expenses.

- Reliability: West-HN's WES-RTLS system undergoes rigorous testing and validation, demonstrating high reliability. West-HN's products use high-quality materials and advanced manufacturing processes, ensuring stable operation in harsh industrial environments. Additionally, West-HN provides professional after-sales service and technical support, ensuring timely resolution of various issues during system use, safeguarding uninterrupted enterprise production operations.

- Intelligence: West-HN's WES-RTLS system integrates advanced IoT technologies and artificial intelligence algorithms, providing intelligent solutions for enterprises. By analyzing real-time location data, the system can optimize production processes, improve inventory management efficiency, and enhance worker safety. For example, by tracking WIP in real-time, the system helps enterprises quickly identify bottlenecks and issues, adjust production plans promptly, and avoid resource waste. Simultaneously, by monitoring worker locations, the system enables contact tracing and collision prevention, improving worker safety.

5.3 How to Choose a Suitable RTLS System for Your Enterprise

- Define Requirements: Before selecting an RTLS system, enterprises need to clarify their needs and objectives. For example, what objects need to be tracked? What is the required positioning accuracy? How large is the area to be covered? What is the budget? Only by defining these requirements can enterprises choose an RTLS system suitable for them.

- Evaluate Technologies: Enterprises need to evaluate different RTLS technologies, understanding the advantages, disadvantages, and applicable scenarios of each. For example, Bluetooth positioning technology is low-cost and easy to deploy but has relatively lower accuracy; UWB positioning technology offers high accuracy and strong anti-interference capability but is more expensive. Enterprises can choose the most suitable technology based on their needs and budget.

- Assess Suppliers: When selecting an RTLS system, enterprises also need to assess the supplier's strength and reputation. A good supplier should have rich industry experience, a professional technical team, and good after-sales service. As a leading global provider of IoT products and solutions, West-HN possesses strong technical capabilities and extensive industry experience, capable of providing high-quality products and services to enterprises.

- Conduct Pilot Testing: After determining the RTLS system supplier and technical solution, enterprises can conduct pilot testing to verify system performance and reliability. Through pilot testing, enterprises can identify system issues and shortcomings, make timely adjustments and optimizations, ensuring the system meets actual needs. In summary, selecting a suitable RTLS system requires enterprises to comprehensively consider multiple factors, including positioning accuracy, cost-effectiveness, environmental adaptability, ease of scalability, and data security. West-HN's WES-RTLS system, with its flexibility, affordability, reliability, and intelligence, is an ideal choice for heavy industrial plants. Enterprises can choose West-HN's ZigBee indoor positioning technology based on their needs and actual conditions to enhance production efficiency and management levels, achieving intelligent transformation.

VI. Application of RTLS Systems in Manufacturing Enterprises

6.1 Work-in-Progress (WIP) Tracking

- Transmit time and motion data, optimize space, reveal anomalies. In the manufacturing process, the movement of objects is often complex and difficult to control. West-HN's ZigBee indoor positioning technology provides enterprises with precise location data, helping them study how objects move. Whether parts on conveyors, work orders between stations, or moving workers, real-time location data allows enterprises to understand the patterns behind these moving parts and optimize spatial layout. For example, movement history data can reveal anomalies in normal production processes, and timing data can quantify the time required for each production stage without manual calculation by workers. This is akin to the evolution of "Taylorism" in factory management since the late 19th century, with West-HN's technology bringing new breakthroughs to modern factory management.

- Provide early warning signals, enhance asset visibility. While real-time location data cannot identify all problems, it enhances asset visibility, making many issues quickly apparent. Examples include a pallet of materials accidentally left at one end of the factory while urgently needed at the other, items on a conveyor slowing to half their normal speed, or perishable items being shipped before their shelf life ends. West-HN's ZigBee indoor positioning technology allows enterprises to grasp these situations promptly, identifying problems before warning indicators become obstacles. For instance, if a critical piece of equipment hasn't changed location for an extended period, it might indicate a malfunction. The system can issue timely alerts for maintenance personnel to address it, preventing impacts on production schedules.

- Generate location-based updates, reduce manual scans and process count. Location data can provide positive updates, such as marking an item's progress from assembly to quality control, or triggering status updates when a manufactured part moves from one step to another. Location-based WIP tracking provides a detailed real-time picture showing the progress and sequence of key processes. West-HN's ZigBee indoor positioning technology excels in this regard, helping to reduce manual scans and the number of required procedures, improving production flow. For example, when a part moves from one station to another, the system can automatically update its status without manual scanning.

- Eliminate manual scanning, improve process accuracy and efficiency. Scanning solutions like barcodes are widely used in manufacturing, but scanning is a manual process prone to human error. West-HN's ZigBee indoor positioning technology can reduce errors through automatic real-time updates, making processes more accurate, efficient, and agile. In a manufacturing process with 30 steps, if manual scanning is used to record each step, a missing scan point could cause issues throughout the process if not immediately noticed by staff. With West-HN's system, all key location points between scans can be mapped, virtually eliminating the scans themselves, improving production accuracy and speed.

- Identify bottlenecks and breakpoints, solve problems based on real data. Bottlenecks and obstacles between the start and end of a project can cause significant losses. With West-HN's ZigBee indoor positioning technology, tracking area-level location data can show the time differences a project spends at various stations. More precise location data or tracking history can help accurately pinpoint where and when each delay began, allowing problem-solving plans to be based on real data, not just best guesses. For example, in a garment manufacturing enterprise, if severe WIP backlog is found at a certain process, West-HN's system can analyze whether it's due to equipment failure or insufficient personnel, enabling targeted problem-solving and improved production efficiency.

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier