Application Background

With the continuous advancement of industry and the internet, fastener distributors and large-scale advanced manufacturing enterprises are gradually adopting the Vendor Managed Inventory (VMI) model. Fasteners, such as screws, nuts, and other non-standard components, are widely used in these enterprises. The core of VMI lies in allowing fastener distributors to autonomously arrange replenishment based on minimum and maximum inventory levels and demand forecasts, ensuring inventory is always maintained within a reasonable range to achieve the desired service level.

Through standardized operational processes, VMI simplifies the traditional transaction model between fastener distributors and large manufacturing enterprises, reduces transaction costs, and effectively decreases inventory across the entire supply chain. Considering the wide variety of fasteners, differing specifications, and the prevalence of custom non-standard parts, the implementation of VMI significantly improves customer service levels, enabling customers to quickly obtain required materials when demand arises. Simultaneously, VMI effectively reduces the inventory pressure on enterprises during the fastener procurement process.

Currently, most assembly-type enterprises require a large number of fasteners. Due to their small size, extensive variety, and high consumption, management often faces numerous challenges. For example, issues such as workers self-picking materials, inconvenient manual distribution, low unit prices but unclear consumption volumes create many pain points in material management. The following are some common problems:

- High procurement costs: Inaccurate grasp of procurement needs leads to duplicate orders, resulting in a large amount of stagnant inventory.

- Severe losses from stockouts: Inability to monitor fastener inventory in real-time poses a risk of stockouts, potentially causing production line stoppages.

- High inventory costs: Excessive stockpiling occupies space and cash flow, leading to high inventory carrying costs.

- Untimely data: Long inventory counting cycles and time-consuming statistics increase the risk of material shortages.

- Significant waste in material requisition: Unregulated and unrecorded material collection in workshops causes serious waste, and manual application and approval processes are complex.

Solution

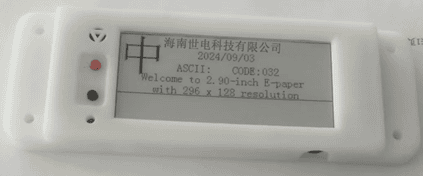

To address the aforementioned issues, West-HN Technology has designed an intelligent shelf system for fastener distributors. This system allows distributors to place intelligent shelves on-site at large manufacturing enterprises, storing various fasteners and related equipment. The intelligent shelves can track inventory quantities in real-time and upload data to a software management backend, enabling distributors to autonomously arrange replenishment based on inventory levels and demand forecasts. This simplifies the procurement process and strengthens collaboration with customers.

Hardware Products

The intelligent tool inventory shelf fully considers the practical needs of equipment management, adhering to the principles of safety, efficiency, and convenience, achieving perfect integration of perception and identification. Through an efficient and flexible configuration, this system helps equipment management users step into a new era of IoT and digital management.

Managed Materials: Fasteners such as screws, nuts, flanges, etc.

Problems it can solve:

- Access Control

- Precise Counting

- Automatic Settlement

- Safety and Reliability

- First-In-First-Out (FIFO) Management

- Rapid Scalability

- High-Frequency Usage Replenishment Alerts

Customer Value

- Remote Monitoring: Enables unattended operation and rapid remote settlement. Using weight detection technology, it accurately monitors retrieval quantities and inventory status. Usage information is automatically uploaded to the software management system upon process completion.

- Intelligent Replenishment Management: Upon receiving replenishment orders, the system can coordinate shipping and delivery arrangements, ensuring timely delivery of fasteners to the production line's intelligent shelves.

- Accurate Demand Forecasting: Through historical data analysis, it accurately determines order quantities, reducing forecast uncertainty and thereby lowering safety stock levels.

- Improved Delivery Timeliness: Fastener distributors can respond more swiftly to the demands of large manufacturing enterprises, enhancing service levels and increasing customer satisfaction.

Through this intelligent shelf solution, collaboration between fastener distributors and large manufacturing enterprises will become closer, achieving continuous optimization and innovation in supply chain management.

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier