I. Project Background and Objectives

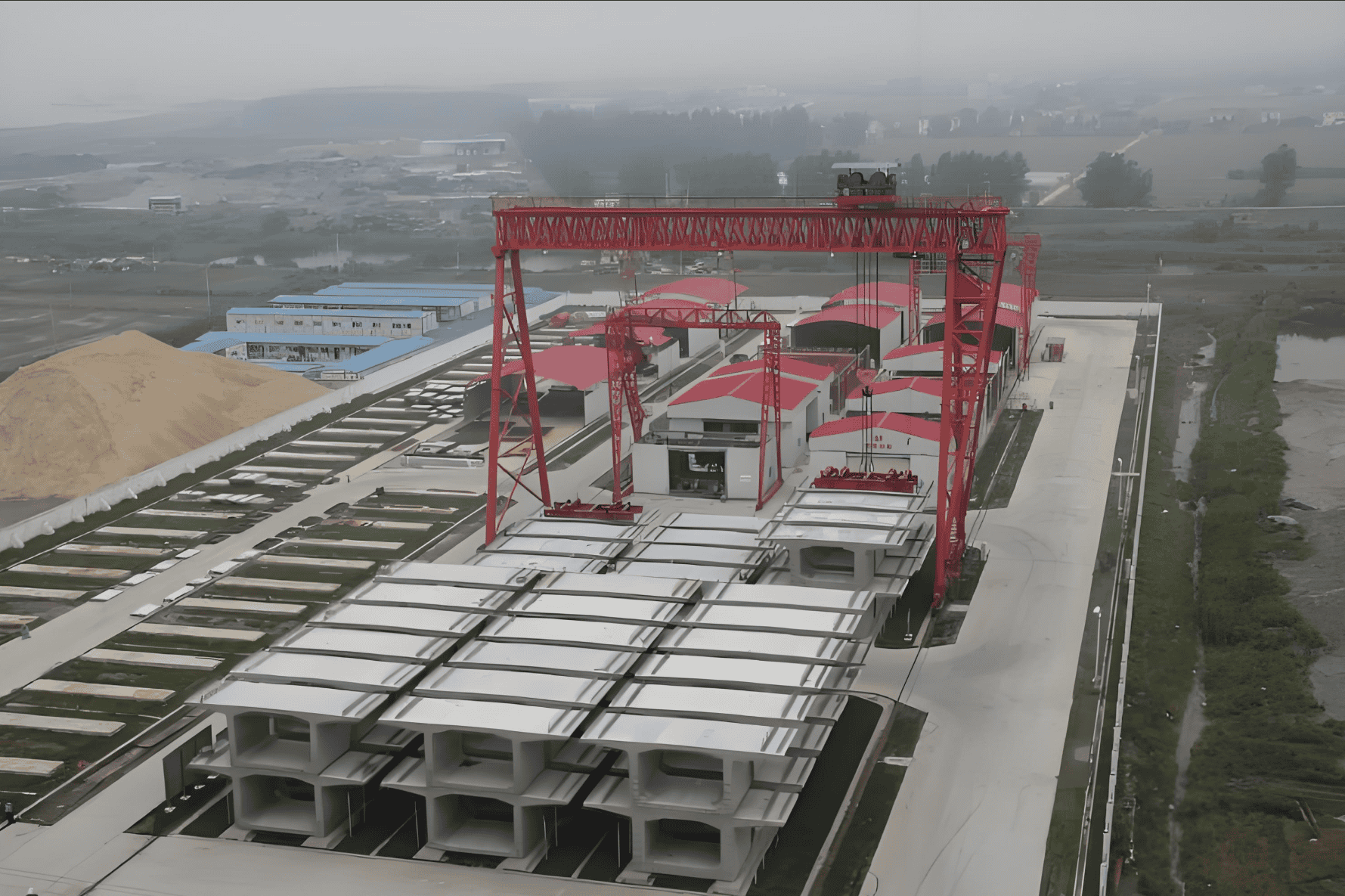

To address the positioning management needs of the segmental beam storage yard in a beam prefabrication plant, this solution utilizes UWB (Ultra-Wideband) ranging technology to build an intelligent management system integrating rapid tag binding/unbinding, real-time positioning of segmental beams, and precise, quick retrieval. Through the wireless deployment of long-endurance UWB tags and solar-powered 4G+ base stations, it solves the problems of difficult positioning and low retrieval efficiency for large prefabricated components during the storage phase, achieving a digital upgrade for the entire lifecycle storage management of segmental beams.

II. Advantages of Core Technology Selection

2.1 Advantages of UWB Ranging Technology

- Centimeter-level Positioning Accuracy: Ranging error ≤30cm, meeting the need for precise differentiation of beam rows, columns, and layers.

- Strong Anti-interference Capability: Highly adaptable to metal components and dusty environments, suitable for complex scenarios in beam prefabrication plants.

- Good Penetration: Can penetrate non-metallic obstacles, suitable for tag signal transmission through the hollow structure of segmental beams.

- High Ranging Stability: Utilizes Time Difference of Arrival (TDoA) technology to avoid environmental reflection interference.

2.2 Hardware Solution Features

- Long-endurance UWB Tags: Battery life ≥3 years (default reporting cycle 30 minutes), IP67 waterproof rating, suitable for outdoor storage environments.

- Solar-powered 4G+ Base Stations: 60W high-efficiency photovoltaic panel + 24Ah lithium battery, supports operation for ≥72 hours during continuous rainy weather.

- Wireless Deployment: 4G full-network transmission, no on-site cabling required, installation period shortened by 60%.

III. System Core Functions and Technical Implementation

3.1 Rapid Tag Binding and Unbinding Function

3.1.1 Binding Mechanism

- Convenient Binding Process: Associate a segmental beam's identity QR code with a tag ID via a mobile terminal (PDA / mobile app) with one-click completion.

- Information Entry: Key information such as beam model, production batch, and strength grade can be entered during binding.

- Batch Operations: Supports batch binding for newly arrived beams (via table import processing).

3.1.2 Unbinding Mechanism

- Single Beam Unbinding: When a beam is dispatched, the association between the tag and the beam is removed via the management platform or mobile terminal.

- Batch Unbinding: Supports batch unbinding operations for entire rows/columns of beams during centralized dispatch.

- Tag Recycling: Unbound tags automatically enter an available state for reuse.

3.2 Real-time Positioning Function

3.2.1 Hardware Deployment Plan

- Base Station Layout: For example, if the storage yard has 6 columns of beams, install 6 corresponding UWB ranging base stations, mounted on the end pillars of each column at a height of 3-4 meters.

- Tag Installation: After beam prefabrication, fix the UWB tag at the center of the hollow bottom section, ensuring the tag faces the base station direction.

- Power Supply & Transmission: Base stations are powered by solar panels + lithium batteries, with data transmitted wirelessly via 4G to the management platform.

3.2.2 Positioning Algorithm Implementation

- Column Positioning:

- Each tag periodically (default 30 minutes) sends ranging signals to all base stations.

- The system collects distance data (D1-D6) from the tag to the 6 base stations.

- The column corresponding to the base station with the minimum distance is identified as the beam's column (e.g., if D3 is minimum, it's in column 3).

- Row Positioning:

- Using the base station of the identified column as a reference, obtain the lateral distance (L) from the tag to that station.

- Combine with preset parameters (single beam width + gap = 1.5 meters, customizable).

- Row calculation formula: Row Number = INT(L/1.5) + 1 (e.g., L=4.2m results in Row 3: 4.2/1.5=2.8→INT(2.8)=2+1=3).

- Layer Positioning:

- Based on the tag installation height and the signal angle difference during base station ranging.

- Combined with the preset height difference between double-layer beams (2.5 meters), automatically determines upper or lower layer.

3.3 Rapid Retrieval Function

3.3.1 Retrieval Process

- User inputs the beam serial number or scans its QR code in the management platform.

- The system immediately retrieves the current positioning data (row, column, layer) for that beam.

- The platform's electronic map displays the precise location.

3.3.2 Technical Support

- Positioning data updates in real-time (delay ≤2 seconds).

- Supports simultaneous multi-target retrieval, displayed distinctly on the map.

- Retrieval results include additional information such as beam storage-in time and estimated dispatch time (reserved).

IV. System Architecture Design

4.1 Perception Layer

- UWB Asset Tags: Installed on the bottom of segmental beams, actively send ranging signals, battery life ≥3 years.

- UWB Ranging Base Stations: 6 units, one per column, responsible for receiving tag signals and calculating distances.

4.2 Network Layer

- Solar Power Supply System: MPPT intelligent charge management with overcharge/over-discharge protection.

- 4G Wireless Transmission: Supports China Mobile / Unicom / Telecom full-network access, with encrypted data transmission.

4.3 Application Layer

- Data Processing Server: Receives base station data, runs positioning algorithms, and resolves beam locations.

- Management Platform: Web-based visual interface, accessible via PC/mobile devices.

- Database: Stores beam information, positioning data, operation logs (data retention ≥3 years).

V. Core Functional Modules

- Tag Management Module

- Tag status monitoring (battery level, binding status)

- Rapid binding/unbinding operation interface

- Real-time Positioning Monitoring Module

- Real-time display of storage yard electronic map

- Dynamic update of beam positions (column, row, layer)

- Statistics on beam quantity and distribution heatmap within the area

- Rapid Retrieval Module

- Multi-condition search (serial number, model, batch, etc.)

- Visual display of positioning results

- System Management Module

- Base station equipment status monitoring

- Positioning parameter calibration (beam width, gap, etc.)

- Operation permission management and log query

VI. Key Points for Implementation and Deployment

6.1 Base Station Installation Specifications

- Install each row's base station on the end pillar, ensuring an unobstructed view towards the beam tags.

- Solar panel tilted 30° facing south (optimal angle for Dongtou area) to ensure sufficient sunlight.

- Base stations evenly distributed based on storage yard length, maximum spacing ≤50 meters.

6.2 Tag Installation Requirements

- Fix the tag at the center of the beam's hollow bottom using strong magnets or bolts.

- Ensure no metal obstruction on the tag surface, with signal emission direction facing the base station.

- Conduct signal test after installation; RSSI value ≥ -85dBm is considered qualified.

6.3 System Debugging Standards

- Positioning Accuracy: Row identification accuracy 100%, column identification error ≤1 column, layer identification accuracy 100%.

- Response Time: From retrieval request to result display ≤5 seconds.

- Data Update: Position information refresh cycle ≤30 minutes (configurable).

VII. Project Expected Benefits

- Management Efficiency Improvement

- Beam retrieval time reduced from an average of 30 minutes to within 5 minutes.

- Tag binding/unbinding efficiency increased by 80%, reducing manual operations.

- Achieves dynamic inventory management, lowering the risk of incorrect or missed dispatches.

- Cost Savings

- Solar-powered 4G base stations eliminate cabling, reducing construction costs by 60%.

- Reusable tags reduce total lifecycle costs by 50%.

- Reduces the need for 3-5 dedicated management personnel.

- Management Level Enhancement

- Achieves digital recording of the entire segmental beam storage process.

- Provides accurate inventory data support for production scheduling.

- Forms a traceable storage management archive.

This solution, tailored to the positioning and retrieval management characteristics of segmental beam storage yards in beam prefabrication plants, employs UWB precise ranging technology and a wireless base station design. It perfectly solves the positioning and retrieval challenges for large components. The system features easy deployment, simple maintenance, and high cost-effectiveness, providing strong support for the intelligent management of beam prefabrication plants.Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier