Addressing the intelligent management requirements for precast beam yard production processes. Taking the case of close-range identification (within 2 meters) for 8 production lines (comprising 8 pouring zones, 8 steam curing zones, 8 curing zones, and 8 tensioning/grouting zones, totaling 32 process areas) and 32 thirty-meter mobile trolleys, along with functional requirements for identifying process names, project area names, mobile trolley names, trolley static/moving status, production line names, and time statistics, we recommend implementing a customized solution using ZigBee semi-active positioning technology. Leveraging its advantages of low power consumption, precise close-range identification, strong anti-interference capability, and dynamic sensing, this technology can comprehensively meet the core needs of your multi-dimensional management scenarios in the production area.

I. Hardware Deployment: Precise Sensing, Building a Digital Correlation Network for Production Elements

1. ZigBee Low-Frequency Signal Source Deployment: The "Smart Identity Carrier" for Mobile Trolleys

Equip each of the 32 mobile trolleys with one industrial-grade ZigBee low-frequency signal source. The signal source features an IP67 high-protection design, capable of withstanding dust, vibration, temperature variations, and humid environments in the production area (with special protection optimization for the high-temperature, high-humidity environment of the steam curing zone). Power supply utilizes solar panels and DC power. Each signal source has a built-in unique ID code, pre-bound with key information through system configuration:

- Basic Identity Information: Mobile trolley name (e.g., "Trolley01", "Trolley32"), affiliated production line name (e.g., "Line2", "Line8"), ensuring unique and traceable trolley identity.

- Dynamic Monitoring Function: The low-frequency signal source is bound to the mobile trolley. Movement from the first ZigBee semi-active tag position upon entering a process to the second ZigBee semi-active tag position, and from the third ZigBee semi-active tag position to the first tag position of the next process area, is identified as moving status. Prolonged identification at the second semi-active tag position indicates stationary status.

The low-frequency signal source is installed on the front side of the trolley, 1.2 meters above ground, using a combination of magnetic adsorption and screw fixation. The signal transmission direction faces the interior of the area, ensuring stable communication with ZigBee semi-active tags. Solar power provides long-term operational endurance, eliminating power supply concerns.

2. ZigBee Semi-Active Tag Deployment: The "Data Collection and Attribute Correlation Hub" for Areas

For the 32 production areas (8 pouring zones, 8 steam curing zones, 8 curing zones, 8 tensioning/grouting zones), the principle of "three tags per area" is adopted for precise deployment, achieving direct correlation between area attributes and processes:

- Each functional area: Install 1 ZigBee semi-active tag on the ground inside the area entrance; install 1 ZigBee semi-active tag on the ground inside the area at the trolley parking stop point near the exit; install 1 ZigBee semi-active tag on the ground 2-3 meters outside the area exit. ZigBee semi-active tags are pre-bound in the software system with core area attributes: process name (e.g., "Pouring Process", "Steam Curing Process"), project area name (e.g., "Line 3 – Curing Zone 05"), production line name (e.g., "Line 3").

- Total deployment across the production area: 96 ZigBee semi-active tags correspond one-to-three with the 32 areas.

3. Reader Deployment: Strategic Placement Based on Site Area for Full Coverage

All reader base stations utilize directional precision identification antennas with a recognition range of 100 meters. They are installed on walls on both sides of the production area at a height of 3 meters, maintaining an unobstructed line of sight with ground-based semi-active tags. Directional signal coverage ensures 100% trigger identification for all tags within the coverage zone, preventing missed reads. Reader base stations connect to the workshop LAN via industrial POE/Ethernet, supporting real-time data upload and local caching (automatic data caching during network fluctuations, synchronized upon recovery), ensuring no data loss.

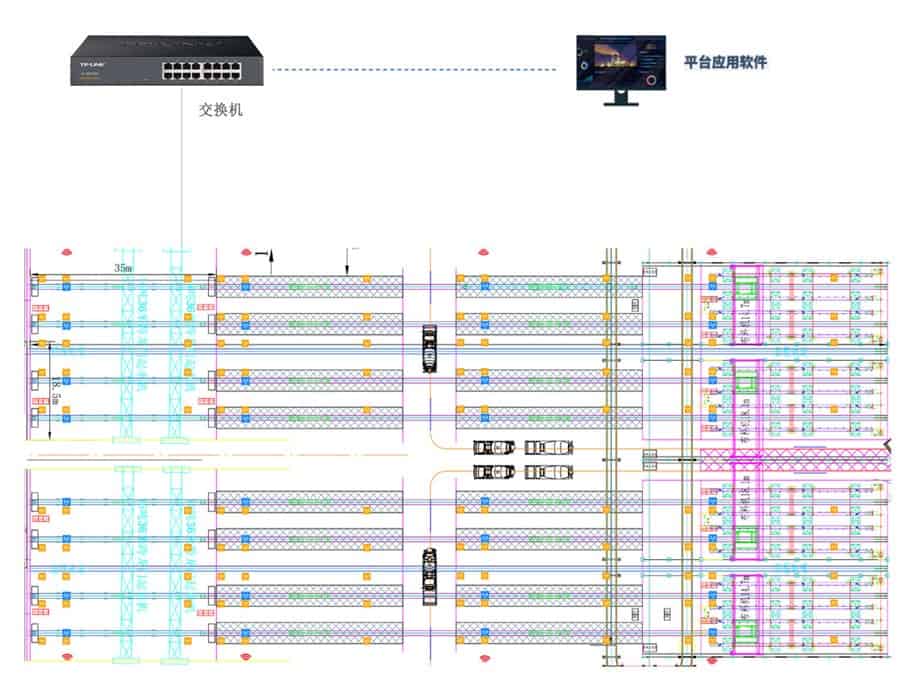

II. Solution Topology

III. System Core Functions: Full-Element Identification + Full-Cycle Statistics, Enabling Transparent Production Process Management

1. Multi-Dimensional Element Automatic Identification: Real-Time Production Information Correlation

- Process Name Identification: ZigBee semi-active tags are pre-bound with the corresponding process type for their area. When a trolley's low-frequency signal source enters the area, the system automatically reads the process information bound to the ZigBee semi-active tag (e.g., pouring zone corresponds to "Pouring Process", tensioning/grouting zone corresponds to "Tensioning/Grouting Process"), achieving precise identification and correlation of process names.

- Project Area Name Identification: ZigBee semi-active tags are bound with unique area codes (e.g., "Line1 – Pouring Zone02", "Line 6 – Steam Curing Zone07"). Upon entry of a low-frequency signal source, the system immediately records the area name, clarifying the trolley's specific location.

- Mobile Trolley Name Identification: Through the trolley name information pre-bound to the low-frequency signal source, the system displays the identity of the trolley currently in the area in real-time (e.g., "Line4 – Tensioning/Grouting Zone03 Current Trolley: Trolley15"), supporting quick location retrieval by trolley name.

- Mobile Trolley Static/Moving Status Identification: The tag's motion sensor collects acceleration data in real-time, uploaded to the system via the coordinator. When acceleration ≤0.1g and persists for 30 seconds, it is judged as "Stationary"; when acceleration >0.1g, it is judged as "Moving". Status changes are updated in real-time on the management interface.

- Production Line Name Identification: Dual verification is performed using the production line information pre-bound to the low-frequency signal source and the production line attribute bound to the ZigBee semi-active tag's area, ensuring error-free identification of production line names (e.g., "Line5"), enabling centralized management by production line dimension.

2. Full-Cycle Time Statistics: Automatic Generation of Process Flow Data

The system automatically records the complete time nodes of trolleys in each process, forming a closed-loop statistical chain:

- Process Entry Time: When a trolley's bound low-frequency signal source enters an area and is first stably identified by the first ZigBee semi-active tag, the system precisely records the time (accurate to the second), e.g., "2025-09-02 09:05:12 Entered Line 5 – Pouring Zone 04 (Pouring Process)".

- Process Working Time: The system automatically calculates "Exit Time – Entry Time". Even if the trolley moves briefly within the area (e.g., minor position adjustments), the continuous dwell duration is still counted, e.g., "Steam Curing Process Working Time: 8 hours 30 minutes".

- Process Exit Time: When a trolley's bound low-frequency signal source begins to leave an area and is first stably identified by the third ZigBee semi-active tag, the exit time is recorded. If the trolley proceeds directly to the next process, the system reverse-calibrates the exit time using the first identification time in the next area, ensuring data accuracy, e.g., "2025-09-02 17:35:12 Left Line 5 – Pouring Zone 04".

All time data is automatically synchronized to the system database, supporting filtering and export to Excel reports by dimensions such as process, production line, and trolley.

3. Visual Management and Dynamic Monitoring: Intuitive Presentation of Production Status

Through the visual interface of the management backend, multi-dimensional real-time monitoring is achieved:

- Area Monitoring Dashboard: Displays the trolley distribution across the 32 areas in real-time, including current trolley name, static/moving status (stationary trolleys marked green, moving trolleys marked yellow), entry time, etc. Clicking on an area reveals detailed data.

- Production Line Monitoring Dashboard: Displays the number of trolleys in each process categorized by production line (e.g., "Line 7 Currently: 2 in Pouring Zone, 3 in Curing Zone, 1 in Tensioning/Grouting Zone"), intuitively presenting production line load balance.

- Trolley Trajectory Tracking: Input a trolley name to query its historical flow trajectory with one click, including entry/exit times, working durations, and status change records for each process (e.g., "Trolley 22 entered Curing Zone at 10:00 on Sep 2, remained stationary for 24 hours, then moved to Tensioning/Grouting Zone").

4. Anomaly Alerts and Data Analysis: Supporting Production Decision Optimization

- Intelligent Anomaly Alerts: Supports custom alert rules, such as "Trolley stationary in Curing Zone for over 36 hours", "Trolley moved but did not enter the next process area within 30 minutes", etc. Upon trigger, alerts are immediately issued via workshop audible/visual alarms and push notifications to management mobile apps, ensuring timely problem resolution.

- Core Data Reports:

- Process Time Analysis Report: Statistics on average working duration, longest/shortest duration by process type, generating efficiency variance analysis compared to standard times, providing basis for process optimization.

- Trolley Status Report: Statistics on stationary/moving duration ratios for each trolley, analyzing equipment utilization, identifying idle trolleys.

- Production Line Efficiency Report: Statistics on daily/weekly process completion volume and area utilization by production line, aiding capacity planning and scheduling optimization.

IV. Solution Value: Full-Process Digitalization, Driving Production Management Efficiency Improvement

- Comprehensive Multi-Dimensional Identification, Meeting Fine-Grained Management Needs

Precisely achieves identification of process, area, trolley, production line names, and monitoring of trolley static/moving status, replacing traditional manual recording. Data accuracy reaches 100%,彻底解决信息碎片化、记录误差大的问题 (completely solving problems of fragmented information and significant recording errors). - Automated Time Statistics, Traceable Process Flow

Automatically records entry, work, and exit times, forming a complete "Trolley – Process – Time – Status" data chain, supporting full-process traceability, providing precise data support for production cycle analysis and process optimization. - Real-Time Status Sensing, Enhancing Production Scheduling Efficiency

Through real-time monitoring of trolley static/moving status, schedulers can quickly identify trolleys ready for transfer (e.g., "trolleys stationary for over 2 hours"), dynamically adjust production plans,预计生产流转效率提升 30% 以上 (expected to improve production flow efficiency by over 30%). - Low Power, Stable, Easy Maintenance, Adapting to Complex Production Scenarios

Zigbee semi-active tags have a battery life of 3-5 years. Readers support Bluetooth configuration management. Deployment and debugging for 32 areas can be completed within 1 day. Hardware investment cost is lower than similar technical solutions, with minimal后期维护成本 (后期维护成本极低).

V. Hardware Product List and Costs

Provided separately as an attachment.

VI. Full-Process Service Assurance: From Deployment to Operation & Maintenance, Worry-Free Throughout

- Customized Preliminary Preparation

Free on-site survey service, conducting comprehensive assessment of the layout and signal environment (focusing on testing signal stability in steam curing zones) for the 32 areas, optimizing tag and coordinator installation locations; provides low-frequency signal source information pre-entry service, ensuring complete alignment with your trolley naming and production line division rules. - Professional Installation and Debugging

Technical team on-site completes equipment installation, precisely binds trolley low-frequency signal sources to trolley names, and ZigBee semi-active tags to area attributes. Conducts 72-hour continuous operation testing:

• Verifies accuracy of trolley static/moving status identification (stationary/moving judgment error ≤5 seconds);

• Ensures time statistics precision (error compared to standard time ≤1 second), guaranteeing data reliability. - Comprehensive Training Support

Provides layered training services (administrator, dispatcher) and detailed operation manuals, focusing on explaining:

• Multi-dimensional data query and filtering (by process / production line / trolley);

• Anomaly alert rule setting and handling procedures;

• Report export and production data analysis methods. - Long-Term Operation & Maintenance Assurance

Provides 1 year of free equipment maintenance + 7×24 hour technical support, supports free system upgrades, and allows flexible expansion based on later新增区域或功能需求 (new area or functional requirements).

We look forward to in-depth communication with you (Contact: Wang Yunhu Phone: 13818128296) to build a production management system for your precast beam yard featuring "full element identification, full status sensing, full time statistics, and fully intelligent scheduling". Let every trolley's flow be more efficient, every process's management more precise, injecting digital动力 (动力) into productivity enhancement.

Content Reviewer: Yao Pinggui Jimme Yao

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier