With the rapid development of urban construction, sanitation work has consistently been a focal point of attention. Key aspects of sanitation transportation supervision include the quantity and distribution of sanitation facilities, ensuring the scheduled frequency of garbage collection is strictly followed, guaranteeing daily waste clearance, timely waste transfer, and efficient dispatch. Sanitation operations primarily utilize RFID technology to collect information at various stages, building a smart sanitation platform to support the development of smart cities.

In many areas, the predominant method of waste handling involves designated vehicles collecting waste from fixed locations at scheduled times daily. To manage information related to the waste volume generated by each bin and the operational status of waste collection, a platform is needed that integrates waste and facility information collection, transport vehicle dispatch, and waste sorting and recycling. This enables centralized management and dispatch, rational resource allocation, and optimization of waste collection and processing efficiency. Through the operation of various system functional modules, relevant data is collected, the real-time status of waste bins and resident behaviors are monitored, and clearance management is optimized. This achieves a networked, intelligent, and information-based waste classification management system in residential areas, with active RFID technology aiding intelligent sanitation waste sorting.

Based on the above context, an RFID-based Smart Sanitation Management system is proposed.

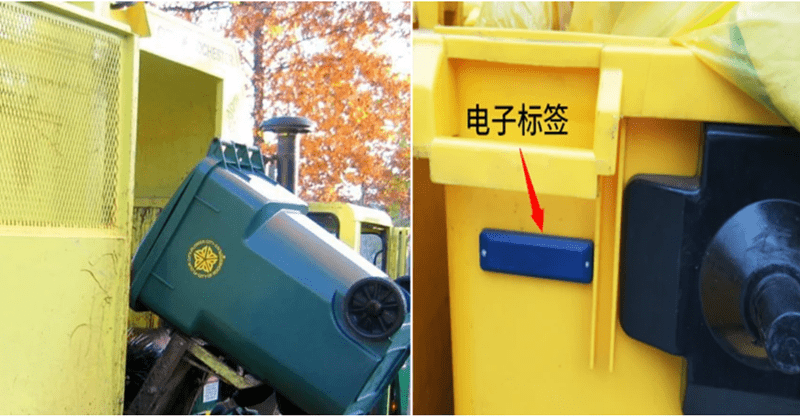

I. Attach RFID Electronic Tags to Waste Bins

Active RFID electronic tags are affixed to standard waste bins, while RFID anti-metal tags are required for metal waste containers. This ensures each waste bin is equipped with a unique RFID electronic tag.

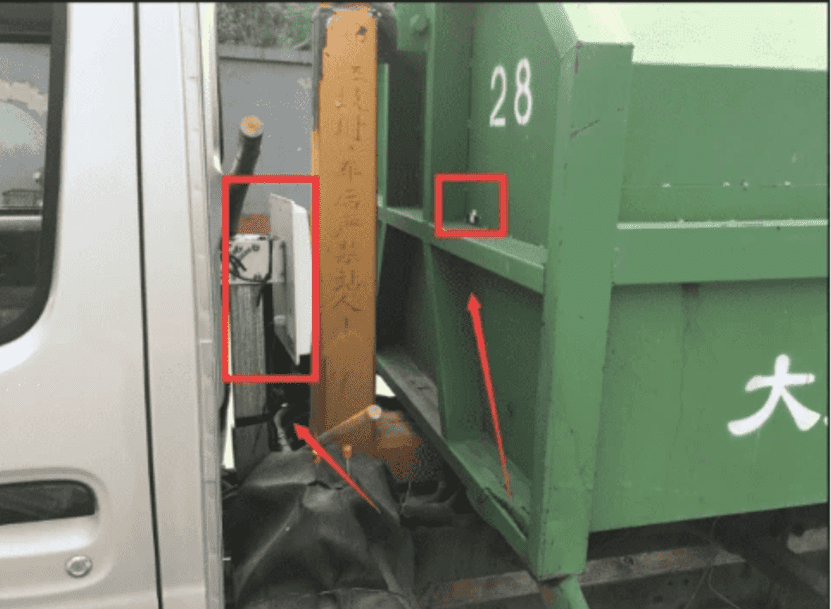

II. Install Long-Range RFID Readers on Sanitation Vehicles

Long-range RFID readers are installed on sanitation vehicles to read the RFID electronic tags on each waste bin or container, enabling statistics on each vehicle's work performance. Sanitation transportation supervision involves installing long-range RFID reader equipment inside garbage trucks to quickly and accurately identify the active RFID electronic tags attached to the waste bins. When a garbage truck begins loading/unloading waste, the onboard long-range RFID reader detects the active RFID tag on the bin being serviced.

III. Install GPS Locators on Sanitation Vehicles

Each sanitation vehicle (water sprinkler, street sweeper, garbage truck, etc.) is equipped with a GPS locator to determine its position, travel routes, etc.

After the long-range RFID reader identifies the operation time and RFID tag ID of a waste bin, the data is transmitted via the vehicle terminal to the central station server, indicating that the bin has been emptied. Its status is then marked as cleared for the day. If cleared within 24 hours, the bin's status appears green in the central station system interface. If the server does not receive the bin's RFID tag data after 24 hours, it indicates the bin has not been emptied. Its status is then marked as uncleared and displayed in red in the system interface.

The residential waste sorting and recycling system employs advanced IoT technology, using long-range RFID readers to collect various data in real-time and seamlessly integrate with the management platform via a self-organizing network system. The system involves RFID tags on waste bins (fixed-point bins, transport bins), long-range RFID readers and vehicle RFID tags installed on garbage trucks (flatbed trucks, collection trucks), vehicle long-range RFID readers installed at residential entrances for vehicle identification and logging, and weighbridges and long-range RFID readers installed at waste transfer stations and final disposal facilities. Each long-range RFID reader can connect to the platform in real-time via wireless modules, enabling real-time association of information such as bin/truck numbers, quantity, weight, time, and location. This achieves full-process supervision and traceability from community waste sorting, transportation, to final processing, ensuring effective and quality waste handling and transportation, and providing a scientific reference basis.

RFID technology enables sanitation management to quickly understand and grasp the distribution of facilities in real-time, thereby monitoring vehicle operation dynamics, real-time supervision of whether garbage trucks are performing collection tasks and their routes, and refined, real-time monitoring of collection tasks. It improves management efficiency at various stages, enhances sanitation work efficiency, reduces management costs, promptly improves the residential environment through timely waste processing, and achieves information-based control.

IV. About Hainan West-HN

Hainan West-HN Technology Co., Ltd. envisions "making standardized industrial IoT simpler." Focusing on the IoT industry chain, we continuously conduct R&D in indoor positioning, sensor control, and data transmission products. Adopting a "Lego-like" production approach, we precisely meet the industrial IoT product demand characterized by small batches and high variety, addressing complex environments and personalized customer needs, truly realizing a new supply-demand relationship with low inventory and high satisfaction.

The company has R&D centers in Shanghai, Suzhou, Chengdu, and Taipei. Upholding the group's nearly 40 years of strong commercial resources and reputation, we firmly believe in the business philosophy of "being industry experts." We excel in channels, are sensitive to the market, focus on products, ensure R&D reliability, production stability, and sales quality, always dedicated to the ultimate satisfaction of personalized scenario needs for industrial IoT customers.

Regarding products, we have Zigbee positioning products developed by our in-house team over more than a decade, as well as UWB positioning products developed by teams in Shanghai and Taipei, meeting different customer requirements for positioning accuracy. Simultaneously, the company introduces Bluetooth positioning products to complement our self-developed solutions, comprehensively satisfying the needs of various customers.

In terms of software support, we integrate overall solutions across industries, actively open interfaces and source code for system integrators to join, facilitate case demonstrations for related system software companies based on our products, and broaden the application of IoT indoor positioning.

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier