I. Product Introduction of Perfluorohexanone Fire Extinguishing Agent

Perfluorohexanone (perfluoro-2-methyl-3-pentanone) fire extinguishing agent is a colorless, odorless transparent liquid at room temperature, with a boiling point of approximately 49°C and an evaporation latent heat 1/25th that of water, making it highly volatile. It features high extinguishing efficiency (comparable to Halon-1301), no ozone depletion potential (ODP=0), a low global warming potential (GWP=1), a NOAEL of 10%, and excellent insulation properties.

Perfluorohexanone extinguishing agent has been used in developed countries such as Europe and America for over 20 years and is listed as a clean agent fire extinguishing agent in the American National Fire Protection Association standard (NFPA 2001). Due to its superior performance including convenient transportation, good compatibility, environmental friendliness, high extinguishing efficiency, and low toxicity, perfluorohexanone is considered the most promising fire extinguishing agent to date for comprehensively replacing transitional halogenated hydrocarbon Halon agents such as heptafluoropropane and trifluoromethane.

★ Fire Extinguishing Principle of Perfluorohexanone Agent:

Perfluorohexanone extinguishing agent exhibits excellent fire suppression effects, achieved through a combination of physical and chemical mechanisms, which can be divided into three processes:

First: Cooling and Extinguishing: After the perfluorohexanone liquid is atomized and sprayed at high speed, it vaporizes upon contact with heat. Due to its large heat capacity during vaporization, it possesses strong heat absorption capability, rapidly depriving the flame of heat and disrupting the fire tetrahedron equilibrium.

Second: Suffocation and Extinguishing: Perfluorohexanone has a high density. During its suspended descent, it can isolate oxygen from the air around the flame.

Third: Chemical Inhibition and Extinguishing: It can capture free radicals in the combustion chain reaction, terminating the chain reaction of flame propagation.

II. Product Advantages of Perfluorohexanone Fire Extinguishing Agent

III. Application Pain Points of Perfluorohexanone Extinguishing Agent and Our Company's Solutions

A major issue with mainstream perfluorohexanone fire suppression systems, both domestically and internationally, is the requirement for high-pressure storage tanks to contain the agent or the use of piping systems for long-distance agent delivery. This leads to high equipment costs. Furthermore, due to the high-pressure aspect, these systems cannot be used in special fields such as aircraft and naval vessels. Additionally, in areas like data centers and cultural heritage preservation, high-pressure fire suppression systems pose a risk of damaging the protected objects.

Addressing the current application pain points of perfluorohexanone extinguishing agent, our company's series of perfluorohexanone fire suppression devices fully adhere to the core principle of using the agent at normal temperature and pressure. These devices offer significant advantages in terms of cost, safety, flexibility, and extinguishing effectiveness. The comprehensive application of our normal temperature and pressure perfluorohexanone fire suppression product portfolio is suitable for fire protection needs in enclosed, semi-enclosed, and confined spaces.

IV. Types of Our Company's Normal Temperature & Pressure Perfluorohexanone Fire Suppression Devices and Patent Application Status

V. Causes of Large Wind Turbine Fires and Current Fire Protection Standards Status

Fire causes are primarily attributed to human and non-human factors. Non-human factors include: generator cable and junction box issues, generator bearing overheating, high temperatures from braking systems, lightning strikes, generator winding short circuits, control cabinet and frequency converter cabinet short circuits, etc. Human factors include: improper maintenance, inadequate management, and improper use of tools.

Wind turbine facilities are typically located in remote areas, positioned high above ground, unattended, and far from rescue centers. Once a fire occurs, the losses can be enormous.

Approximately 2~3‰ of wind turbines experience fires annually, with large wind turbines having a higher probability. Many wind turbines still lack automatic fire protection measures, making it urgent to equip them with automatic fire suppression systems. Currently, automatic fire safety systems for wind turbines are almost non-existent, highlighting the need to research and implement cost-effective system technologies and develop corresponding standards.

Currently, automatic fire safety systems for wind turbines are almost non-existent, highlighting the need to research and implement cost-effective system technologies and develop corresponding standards.

VI. Overview of the Normal Temperature & Pressure Perfluorohexanone Jet Fire Suppression System for Large Wind Turbines

Solution Overview

The fire protection requirements for large wind turbines follow the principle of "early detection, early intervention." Utilizing a fiber optic continuous temperature monitoring system as the primary method, combined with various on-site sensors such as multi-parameter gas sensors, the system provides advanced detection and warning for the initial stages of thermal runaway in key protected areas within the nacelle, aiming to extinguish fires in their incipient stage!

The normal temperature and pressure perfluorohexanone jet fire suppression device, when paired with necessary on-site sensors, can achieve the controlled application requirements for perfluorohexanone in large wind turbine nacelles, ensuring sufficient concentration and injection duration (quantity) for effective on-site fire suppression.

Key Protected Areas of Large Wind Turbines

- Drive motors, control cabinets, power cabinets, etc., inside the hub;

- Generator, hydraulic system, gearbox, braking system, yaw drive, control cabinet, capacitor bank, connecting cables, etc., inside the nacelle;

- Converter, control cabinet, transformer, base electrical cabinet, computer cabinet, etc., at the tower base.

VII. Advantages and Features of Our Company's Large Wind Turbine Fire Protection Solution

- Precise Monitoring: Predicts fire conditions in their incipient stage. Online monitoring of various thermal runaway characteristic substances (continuous fiber optic temperature sensing, composite gas sensors, thermal runaway sensors, temperature sensors, smoke sensors, etc.) accurately detects thermal runaway locations. Initially, pre-discharge of perfluorohexanone agent is applied to the identified fire risk points. If the fire spread remains uncontrolled, the system automatically initiates the full-flooding fire suppression process for the entire large wind turbine nacelle.

- Heat Absorption and Cooling: Sufficient discharge of perfluorohexanone extinguishing agent suppresses fires while providing non-damaging cooling to the affected equipment.

- Thermal Runaway Suppression: Multiple electrical discharges of perfluorohexanone agent inhibit thermal runaway.

- Customized Nozzle System: A combination of dedicated fluid delivery hoses, quick connectors, and customized nozzles supports on-site cutting and rapid installation. Customized nozzles enable rapid atomization, accelerating fire suppression speed.

- The nozzle system can be installed at key fire warning units within the large wind turbine, allowing flexible deployment. Combined with full-nacelle flooding agent discharge, this achieves the goal of dual-protection fire suppression.

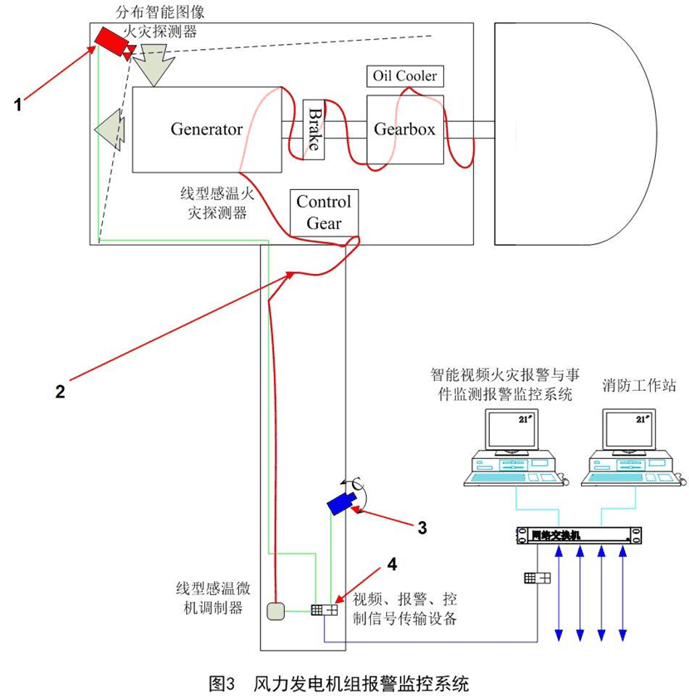

▲ Schematic Diagram of the Alarm System for the Large Wind Turbine Fire Protection Solution

Optional online monitoring sensors for various fire thermal runaway characteristic substances: Image flame detectors, continuous fiber optic temperature sensing, composite gas sensors, thermal runaway sensors, temperature sensors, smoke sensors, etc.

▼ Schematic Diagram of the Perfluorohexanone Discharge System for the Large Wind Turbine Fire Protection Solution

Perfluorohexanone storage tanks at the base of multiple wind turbines are interconnected via a piping network, forming a distributed liquid storage system.

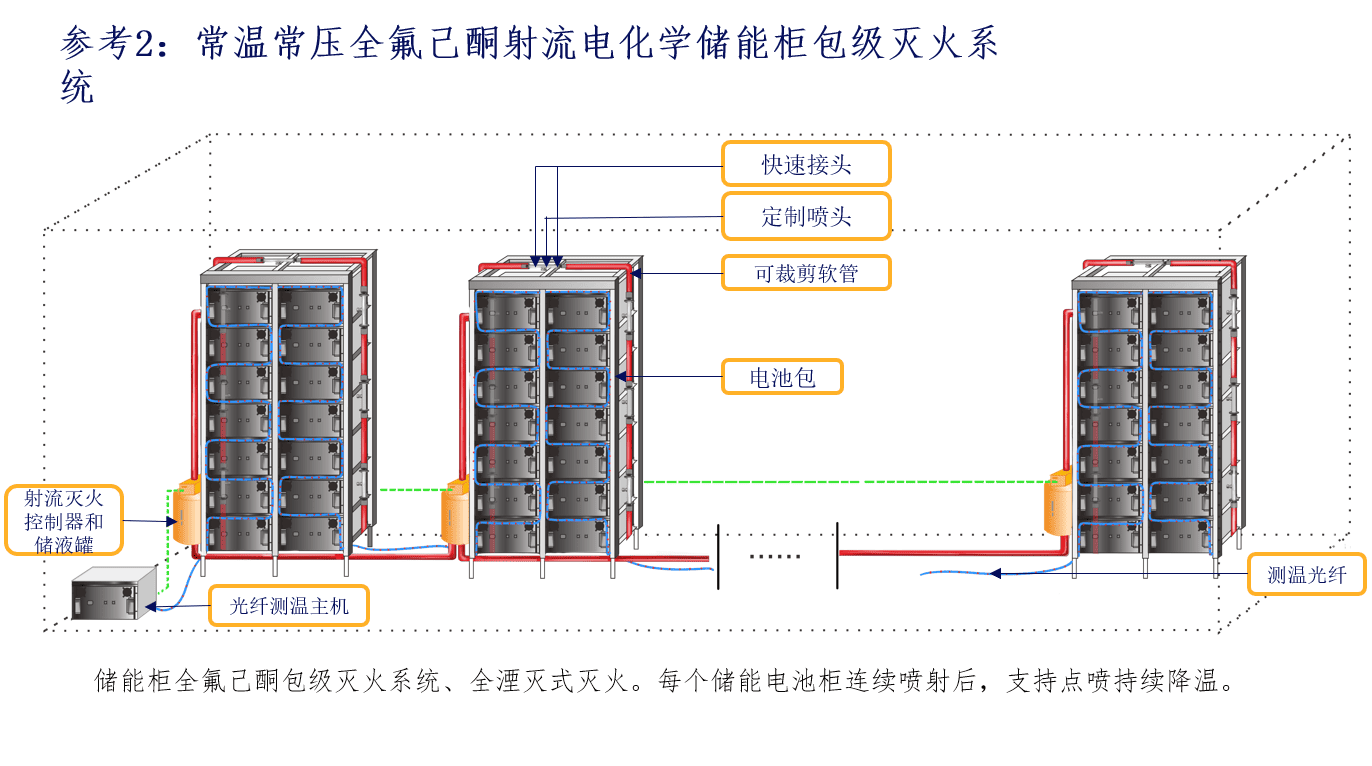

The following are schematic diagrams of the normal temperature and pressure perfluorohexanone jet fire suppression system applied in electrochemical energy storage cabinets. Case one is a full-flooding fire suppression system. Case two is a pack-level fire suppression system. In large wind turbines, this is equivalent to deploying a small-scale normal temperature and pressure perfluorohexanone jet fire suppression system for each key protected area. Each system can have its own sensors or share sensor information, continuously monitoring fire suppression status to decide whether to activate the full-nacelle flooding fire suppression system. This is the implementation principle of the dual-protection fire suppression system.

Content Reviewer: YAO Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier