The Wireless Grain Bin Temperature Monitoring System is a new-generation grain bin temperature measurement and control system developed with complete independent intellectual property rights. It is based on low-power wireless RF modules and utilizes Wireless Sensor Network (WSN) technology, also known as the Internet of Things (IoT), which is recognized as one of the ten technologies with the most significant impact on changing the world in the 21st century.

As a crucial component of the multi-parameter grain condition monitoring system, the Grain Bin Wireless Temperature Sensor System requires no on-site professional installation or field service, is not easily damaged, significantly reduces costs, and greatly facilitates user operation. It completely abandons the traditional crisscrossing wired networks, fundamentally solving issues such as frequent post-fumigation failures caused by extensive cable coverage, vulnerability to lightning strike damage, numerous difficult-to-seal connection points, and susceptibility to fumigation corrosion. It also addresses the high overall system cost, difficult installation and debugging, and the susceptibility of lines to mechanical damage during grain rotation and bin transfer. Furthermore, the GPRS gateway can also integrate other grain condition data such as moisture, grain pests, and phosphine concentration.

The Wireless Grain Bin Temperature Monitoring System consists of a 4G gateway, wireless digital temperature measurement cables (with batteries), and other components. Combined with the wireless air temperature and humidity sensor (already completed), and planned sensors including wireless grain temperature & moisture sensors, wireless grain pest sensors, wireless phosphine gas sensors, wireless oxygen sensors, wireless carbon dioxide sensors, wireless grain level sensors, and wireless switch controllers, it can form a complete wireless grain condition monitoring system. All system parts are powered by two standard 3.3V 2300mAh batteries. With a scheduled data upload interval of 15 minutes and a response time of 10 seconds, a normal service life of 3 years is guaranteed. Outdoor equipment can also be powered by solar energy, with a lifespan exceeding ten years.

The response time interval of 10 seconds is adjustable. However, shorter intervals result in higher product power consumption. The benefit of a short response time is that when users temporarily need to read data from a specific temperature sensor, they can obtain the temperature data within the set response time.

Salient Features

- Completely wireless grain condition monitoring and control system, requiring no connection to power or communication cables

- Simple on-site installation. Construction only requires placing the corresponding equipment at designated locations, without any construction work on the granary's building facilities such as trenching, grooving, or drilling. It also saves on cable costs and various construction expenses like burial, conduit installation, and wiring, potentially reducing installation and debugging costs by over 90%.

- Except for the computer system, all other system components can be powered by standard 1.5V dry batteries; outdoor equipment can also utilize solar power

- System operation is unaffected by power outages in the storage area. If the computer system uses a portable laptop, it can function normally anywhere within the storage area.

- Completely resolves issues of lightning strike damage and mechanical damage

- Traditional wired methods, due to interconnected equipment and extensive cable coverage, are prone to lightning strike damage. Simultaneously, lines are susceptible to mechanical damage during grain loading and unloading, leading to frequent failures. The West-HN Grain Condition Monitoring System, having no cable connections, thoroughly solves these problems.

- Timely system repair, eliminating the need for on-site after-sales service from the equipment manufacturer

- Since there are no connections between devices, if a device is damaged, the user only needs to perform a simple replacement with a spare part and exchange the damaged device with the manufacturer.

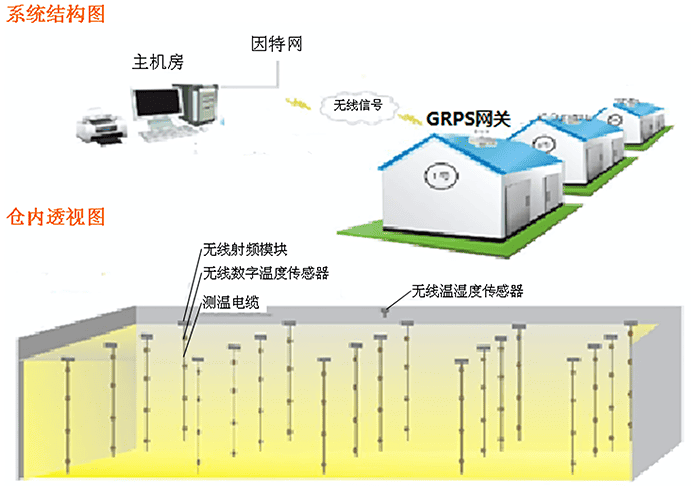

System Block Diagram

Installation Steps for Temperature Measurement Cables

- Product Completeness

- The temperature measurement cable consists of two parts:

- The temperature sensor cable section, composed of multiple temperature sensors (DS18B20), connecting cables, reinforcement ribs, and a protective sheath.

- The electronic component section, including the MCU, LoRa communication module, housing, etc.

- After passing factory inspection, the entire cable is packaged and shipped to the user.

- If a temperature sensor or electronic component fails, the entire temperature measurement cable is replaced. Therefore, maximizing product reliability is essential.

- The temperature measurement cable consists of two parts:

- On-site Installation

- Users install the temperature measurement cables by evenly distributing and inserting them into every part of the grain bin according to its specific location and shape. During on-site installation, cables can be picked up arbitrarily without specific numbering or sequencing requirements. After the cables are inserted into position, the manager will issue an inspection command via the central node. Using the product's human-machine interaction function, they will observe and record the installation location of each cable and mark the corresponding position on the backend management platform interface. When the system runs, the temperature at any point can be understood.

Introduction to Wireless Temperature & Humidity Sensor

The Wireless Temperature & Humidity Sensor conveniently transmits the temperature and humidity values of measurement points wirelessly. These are received by the GPRS gateway and sent to the host computer, enabling the establishment of a temperature and humidity monitoring system without the need for wiring, making construction simple.

⦾ Technical Specifications:

- Temperature Measurement Range: -10℃ — +60℃

- Temperature Measurement Accuracy: ±0.5℃ ( -10℃ — +60℃ )

- Humidity Measurement Range: 1% — 99% (non-condensing)

- Humidity Measurement Error: ±3%RH ( 25℃, normal humidity 30%-70% )

- Wireless Transmission Rate: 9600 BPS (fixed)

- Low-power transmission, maximum transmit power 20dBm

- ISM band, no frequency point application required

- Carrier Frequency: 433MHz

- High anti-interference capability and low bit error rate

- Based on LoRa modulation, employing efficient Forward Error Correction (FEC) channel coding technology, improving data resistance to burst and random interference, with strong diffraction performance.

- Long transmission distance

- Under line-of-sight conditions (open area) with antenna placement >2 meters, reliable transmission distance >1.5km (at 9600 BPS).

- Sampling Interval: 60S (can be customized according to customer requirements)

- Power Supply Voltage: Battery

- Battery Life: 2600mAh battery, sampling every 60S, usable for over 3 years

- Dimensions: 100 X 80 X 30 (mm)

Hainan West-HN Technology

Hainan West-HN Technology Co., Ltd. envisions "making industrial IoT standardization simpler." Focusing on the IoT industry chain direction, it continuously researches and develops in the fields of indoor positioning, sensing control, and data transmission products. Adopting a "Lego-like" production approach, it precisely meets the industrial IoT product characteristic of small quantities and high variety, providing solutions for complex environments and personalized customer needs, truly realizing a new supply-demand relationship with low inventory and high satisfaction.

The company has R&D centers in Shanghai, Suzhou, Chengdu, and Taipei. Upholding the group's nearly 40 years of strong commercial resources and reputation, it firmly believes in the business philosophy of "being an industry expert." It excels in channels, is sensitive to the market, focuses on products, ensuring R&D results are reliable, production is stable, and sales maintain quality, always dedicated to the ultimate satisfaction of industrial IoT customers' personalized scenario needs.

Regarding products, we have Zigbee positioning products developed by our in-house team over more than a decade, as well as UWB positioning products developed by teams in Shanghai and Taipei, meeting different customer requirements for positioning accuracy. Simultaneously, the company also introduces Bluetooth positioning products to complement its self-developed solutions, aiming to comprehensively satisfy the needs of various customers.

In terms of software support, we integrate overall solutions from various industries, actively open interfaces and source code for system integrators to join, and facilitate related system software companies in creating case demonstrations based on our products, broadening the application of IoT indoor positioning.

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier