I. IoT Solution for Smart Factory Energy Consumption Management and Control

The West-HN Smart Factory Energy Consumption Management and Control Solution is based on edge computing. By utilizing downstream energy consumption and environmental sensors along with terminal control devices, this solution enables intelligent management and control of a factory's electrical equipment and resources such as water, electricity, and gas. This allows for real-time monitoring and control of various energy consumption within the factory, as well as monitoring and adjustment of environmental parameters.

Through optimization of control strategies, this solution helps factories avoid energy waste, thereby improving energy utilization efficiency. This intelligent energy consumption management and control solution aids factories in achieving energy conservation and emission reduction, lowering production costs, and aligns with sustainable development requirements.

II. Application Device Selection

This solution is comprehensive and forward-looking, primarily aiming to achieve coverage of IoT communication gateways across entire factory buildings and premises. It supports multiple uplink and downlink communication technologies to connect various wireless and wired terminal devices. This enables online monitoring, automatic collection, and storage of various energy consumption data and energy efficiency indicators, providing flexible and diverse query methods. Additionally, the solution includes functionalities such as remote control of high-energy-consumption industrial and mining lights, provision of environmental collection sensors, and remote on/off control for special equipment.

This integrated smart factory energy consumption management and control solution can help factory areas achieve goals like energy conservation, emission reduction, improved production efficiency, and optimized energy utilization. Through remote monitoring and control, factory management personnel can manage and adjust energy consumption more precisely, thereby achieving the objectives of energy conservation, emission reduction, and cost savings.

III. Case Study Site Introduction (A Large New Energy Factory Building)

The new energy factory building has three floors, with the on-site conditions roughly as follows:

- Typical building HVAC pump exchange room, featuring numerous mechanical and electrical devices, many metal structures, and a complex spatial and electromagnetic environment.

- The site has a large spatial area, with a depth of 290 meters, and includes concrete partition walls and sheet metal walls.

- The customer's PLC equipment is widely distributed across the site, presenting a typical wireless testing environment.

The on-site environment is relatively complex, imposing certain requirements on the stability and reliability of data transmission for wireless communication devices.

Network Topology:

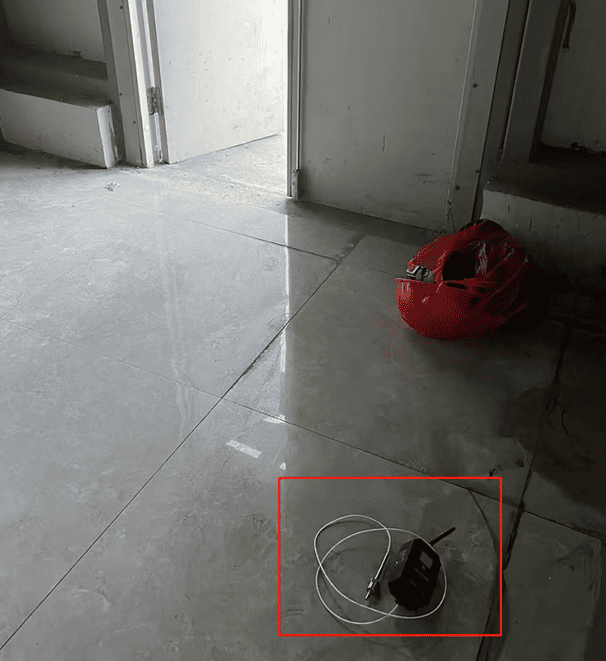

Serial Port Assistant Tool, Router, Industrial Interconnection Host Computer, Gateway, and Node Sub-devices

✦ Features:

- Sub-devices periodically send and receive data.

- Supports statistics on various actions and events of sub-devices.

- Supports real-time automatic saving of test data via serial port.

- Supports real-time viewing of data packet transmission and reception via serial port.

Using local services, the gateway and PC are connected to the same router within the same local area network (LAN). The gateway connects to the PC via a serial port for print output; multiple sub-devices communicate wirelessly with the gateway.

Hainan West-HN Technology Co., Ltd.

Hainan West-HN Technology Co., Ltd. envisions "making standardized industrial IoT simpler." Focusing on the IoT industry chain, we continuously conduct R&D in areas related to indoor positioning, sensing control, and data transmission products. Adopting a "Lego-like" production approach, we precisely meet the small-batch, high-variety demand characteristics of industrial IoT products, providing solutions for complex environments and personalized customer needs, truly realizing a new supply-demand relationship with low inventory and high satisfaction.

The company has R&D centers in Shanghai, Suzhou, Chengdu, and Taipei. Upholding the group's nearly 40 years of strong trade resources and reputation, we firmly believe in the business philosophy of "being experts in the industry." We excel in channels, are sensitive to the market, focus on products, ensure reliability in "R&D," stability in "production," and quality in "sales," always dedicated to the ultimate satisfaction of personalized scenario needs for industrial IoT customers.

Regarding products, we have both Zigbee positioning products developed by our in-house team for over a decade and UWB positioning products developed by teams in Shanghai and Taipei, meeting different customer requirements for positioning accuracy. Simultaneously, the company also introduces Bluetooth positioning products to complement our self-developed solutions, aiming to comprehensively satisfy the needs of various customers.

In terms of software support, we integrate overall solutions from various industries, actively open interfaces and source code for system integrators to join, and facilitate related system software companies in creating case demonstrations based on our products, broadening the application of IoT indoor positioning.

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier