Application Background

Are the maintenance procedures in automotive 4S shops complex and vehicle retrieval slow? Are car owners unable to stay informed about their vehicle's progress in a timely manner, leading to a poor experience? With the continuous development of location-based IoT information, West-HN Technology has transitioned its self-developed ZigBee dual-frequency positioning technology from production lines to end-user storesfronts. Automotive 4S shops have begun deploying ZigBee dual-frequency positioning systems for maintenance vehicle management, precisely sensing customer vehicle location information and making procedure progress clear at a glance.

Application Overview

Multi-Process Operation Timeliness Management and Tracking System

In traditional automotive 4S repair services, many management shortcomings have resulted in poor customer service experiences. Based on ZigBee dual-frequency tag positioning technology, West-HN Technology has developed a Multi-Process Operation Timeliness Management and Tracking System. Through a series of sub-application systems including an operation dashboard system, an electronic tag activator naming, tracking, and reporting system, and a service process logic positioning management system, this solution integrates process location, service progress, and location-based IoT technology. This enables the multi-process operation timeliness management system to achieve automation, digitization, and visualization, effectively realizing quantifiable management of personnel efficiency and attendance in multi-process scenarios such as automotive 4S shops.

Industry Pain Points

- Inefficient process operations

- High difficulty in personnel management

- Inability to grasp customer service progress

- Difficulty in quantifying personnel efficiency and attendance

West-HN Dual-Frequency Activation Tags and Activators ⬇️

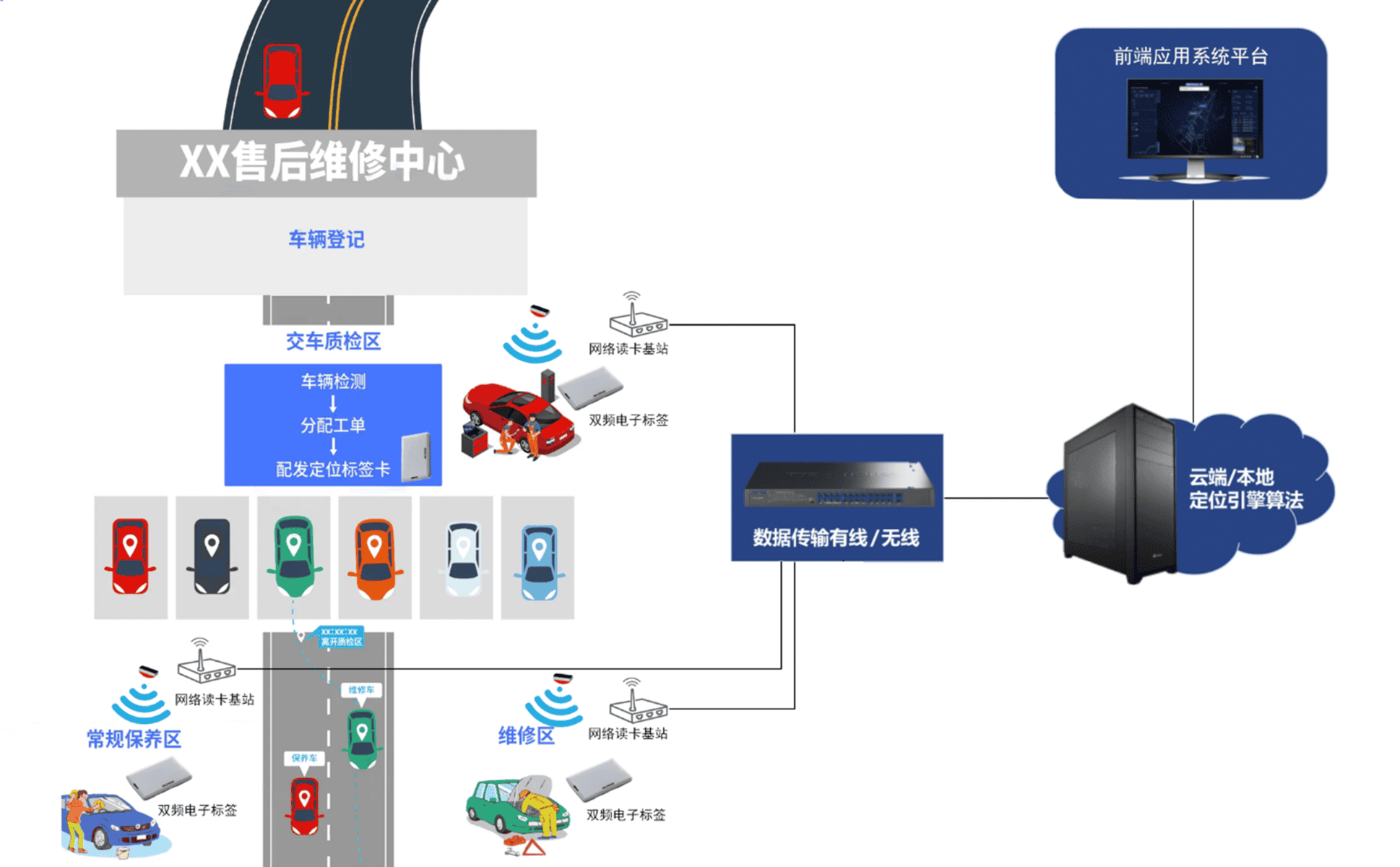

Solution Architecture

Vehicle Registration & Quality Inspection: After license plate and personnel registration for the maintenance vehicle, the vehicle undergoes inspection and assignment, and a dual-frequency positioning tag card is issued and bound to the license plate.

Vehicle Service Item Zoning: After passing quality inspection, vehicle service items are managed by zones, which can be divided into routine maintenance areas and repair areas. Customers can view vehicle service progress and location information at any time from the control center's large screen; service progress for vehicles can be reviewed via playback.

Vehicle Delivery: Upon completion of the service process, customers can use the dual-frequency positioning tag to query service nodes and details. Simultaneously, work hours and efficiency are calculated, enabling real-time understanding of procedures and maintenance progress, thereby enhancing the user experience.

Application Features

- Precise Process Tag Naming Management

- Dynamic Tracking of Serviced Objects via Electronic Tags

- Automatic Process Matching and Reporting

- Statistics on Work Hours per Process and Personnel Efficiency Analysis

Value & Advantages

- Enhances Process Management and Statistical Efficiency

- Improves Customer Perception of Service Effectiveness

- Achieves Automated and Visual Personnel Attendance Tracking

- Optimizes and Coordinates Process Work Hours and Personnel Efficiency

Content Reviewer: Yao Pinggui (Jimme Yao)

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier