UWB Chemical Plant Personnel Safety Management Solution

I. Industry Status and Demands

The chemical industry is characterized by high temperatures, high pressure, flammability, explosiveness, and toxicity, making it inherently hazardous. Additionally, features such as large-scale and dense production facilities, complex processes, and tightly coupled production stages contribute to a higher risk level compared to other industrial sectors. The chemical industry primarily faces the following safety pain points and demands:

Pain Point 1: Difficulty in Personnel Management. Chemical plants have numerous and dispersed personnel, making it challenging to track their real-time locations accurately, obtain precise headcounts in workshops, manage effectively, and improve efficiency.

Pain Point 2: Inefficient Patrol Inspection. Traditional patrol methods relying on inspection tags are prone to missed or incorrect checks. Supervision and assurance of inspection results are lacking.

Pain Point 3: Inadequate Control. The high-risk production environment and numerous pieces of equipment in chemical plants make comprehensive supervision of key areas difficult. Unauthorized entry by visitors or non-professionals into these areas can easily lead to misoperations and safety incidents.

Pain Point 4: Information Silos. Current monitoring and management systems in chemical plants, such as video surveillance, personnel management, and access control systems, often operate independently. Information forms isolated islands, failing to provide emergency management platforms and comprehensive decision support for managers at all levels, resulting in low management efficiency.

With the rapid development of internet and IoT technologies, chemical plants are also on the path of digital-to-intelligent transformation. To tightly integrate traditional production data, personnel data, and other efficiency and safety-related data, Hainan Shidian Technology has launched a precise personnel positioning management system based on UWB technology. This system provides accurate location services to the intelligent platforms of chemical plants, helping to address the aforementioned pain points.

II. Overall Solution Architecture

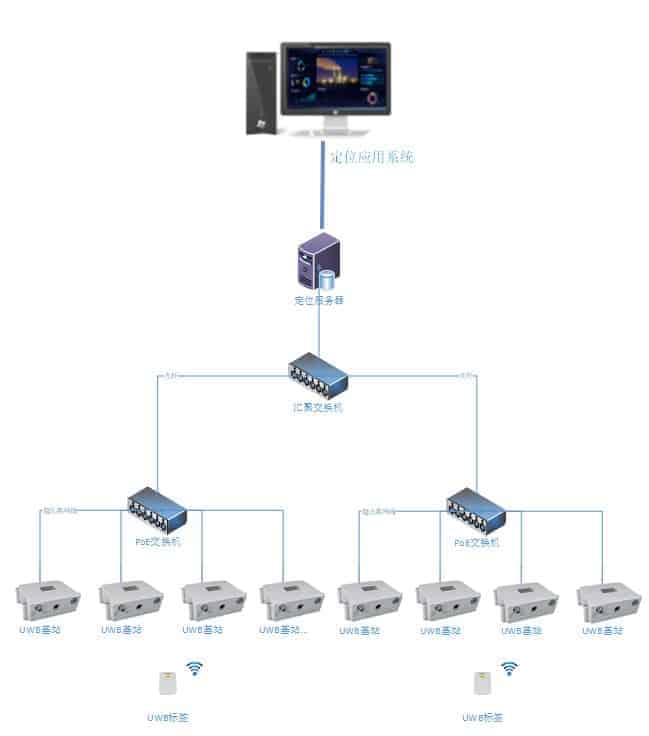

The system comprises UWB tags, UWB explosion-proof base stations, positioning engine software (C/S architecture), and a positioning application system. UWB tags and base stations communicate via UWB pulse signals. The base stations transmit received tag data via 5G networks or wired Ethernet to the LS1000 positioning engine for data analysis and processing. The processed precise location data is then transmitted to upper-layer applications through open APIs.

The system components are as follows:

UWB Tags: Available in card-type and wristband styles, attached to personnel or assets. They periodically transmit UWB signals containing tag ID information.

UWB Explosion-proof Base Stations: Communicate with positioning tags and relay information back to the positioning engine algorithm software.

Positioning Engine Algorithm Software: Deployed on-premises, it collects underlying data and processes it through positioning algorithms to obtain the precise coordinates of tags.

Positioning Application Software: Can be deployed on-premises or in the cloud. This application-layer software implements basic functions like location display and track playback, as well as business functions extended from location data, such as electronic fencing, intelligent patrol inspection, attendance statistics, and video linkage.

III. Related Products

Positioning Tags and Explosion-proof Base Stations

UWB Base Station

UWB Explosion-proof Base Station WE-RAB100M

UWB Tag

UWB Card-type Electronic Tag WE-T241-C

UWB Tag

UWB Wristband/Hard Hat Electronic Tag WE-T206-H

If you have any questions about this, please contact us.

IV. Solution Features

Feature | Description |

Real-time Personnel/Vehicle Positioning | Personnel positioning accuracy of 0.3-1 meter, real-time vehicle speed display. |

Historical Track Query | Query the movement track of a specified person within a certain period. |

Personnel Roll Call | Obtain activity information of personnel within a specified area. |

Entry/Exit Control | Monitor and record personnel entry/exit information in real-time using entry beacons. |

One-key SOS | Built-in SOS button on the tag; press and hold for 3 seconds to trigger audible and visual alarms on the system platform. |

Electronic Fencing | Configurable electronic fence types: overstaffing, understaffing, unauthorized job switching, leaving post, disappearance, etc. |

Patrol Inspection Management | Use drawing tools to create circular, polygonal, or rectangular fence areas; configure basic patrol area info, inspection plans, generate reports, etc. |

On-duty Statistics | Real-time statistics of personnel count in each area. |

Asset Positioning | Monitor fixed assets by attaching asset positioning tags. |

Alarm Record Information Management | Visual icon-based display for different types of alarm information. |

Data Statistics & Query | Display statistical alarm counts; provide query and printing of annual, monthly, and daily alarm statistics. |

Positioning Information Heat Map | Statistically analyze personnel/vehicle distribution data on a positioning map and generate a heat map display. |

Location Tracking | Query a snapshot of personnel location distribution at a specific moment. |

Visitor Management System | Register external personnel (add, modify, delete) and manage tag issuance and collection for them. |

Video Linkage | Import video streams into the software platform for convenient viewing of key area situations. |

Hardware Status Management | Query working status information of hardware like positioning base stations and beacons; display device locations on the map for maintenance. |

Multiple Map Format Support | Supports various map formats: Oblique Photography, Hummingbird Cloud Map, Gaode Map, 3D Modeling, 2D Maps. |

Editor-in-Chief:

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier