I. Industry Status and Demands

Substations are the core link in power transmission and represent a typical high-risk work environment. Due to their highly structured and similar layouts, any slight negligence can easily lead to safety incidents. Leveraging the Ubiquitous Power Internet of Things (UPIoT) construction enables the digitalization, informatization, and visual management of smart substation operations. Current safety management issues in substations are as follows:

Pain Point 1: During maintenance, some areas remain operational. For maintenance personnel, there is a risk of entering wrong zones, lacking supervision and alarms for hazardous areas. Traditional maintenance supervision relies on manual monitoring, which can lead to dangerous events if personnel are negligent or violate operating procedures, not only increasing labor costs but also posing safety hazards.

Pain Point 2: For outdoor elevated work, such as operations on 110kV and above main transformer bushings, workers' safety ropes are tied to horizontal safety ropes, and positioning ropes are tied to the bushings. The lack of secure high anchor points for safety belts, or using them low for high work, increases fall risks without timely rescue. Climbing up/down transformers or moving on them offers no protection. Oil stains on bushings and equipment bodies can cause slips. Operations near live hazardous equipment lack timely warnings.

Pain Point 3: In major grid safety incidents both domestically and internationally, severe misoperations like grounding live lines or energizing grounded lines still occur. While current microcomputer-based "Five Protections" devices prevent incorrect grounding installation or removal through interlocking substation grounding piles, they cannot address the safe removal of temporary grounding wires within the substation. Real-time monitoring is unavailable for whether issued grounding wires are installed, their installation locations, or if all are removed after work completion, creating security vulnerabilities in existing anti-misoperation systems. Energizing with grounding lines attached cannot be promptly detected and stopped.

Addressing the pain points and challenges in the power substation industry, Hainan Shidian Technology has launched a precise personnel positioning management system based on UWB technology. It provides substation management and maintenance personnel with accurate location service information, time data, trajectory information, etc. By setting electronic fences to trigger alarms, it enables timely detection of abnormal behaviors, automates coordinated actions of supervision facilities, improves emergency and incident response speed, and forms a multi-dimensional prevention pattern integrating human, technical, physical, and joint defenses.

II. Overall Solution Architecture

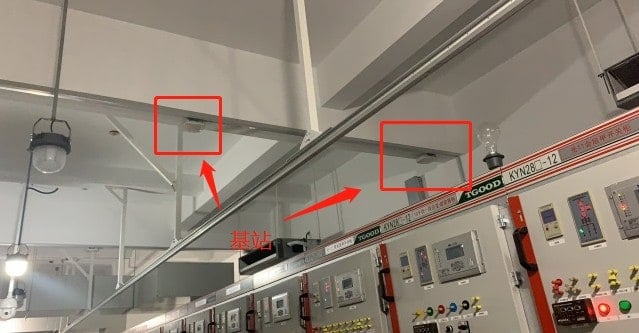

The system includes UWB tags, UWB explosion-proof base stations, positioning engine software (C/S architecture), and a positioning application system. Positioning tags and base stations communicate via UWB pulse signals. Base stations transmit received tag data via 5G networks or wired Ethernet to the LS1000 positioning engine for data analysis and processing. The processed precise positions are then transmitted to upper-layer applications through open API interfaces.

System components are as follows:

UWB Tags: Available in card-style and wristband-style, attached to personnel or assets, periodically transmitting UWB signals containing tag ID information.

UWB Outdoor Wired Base Stations: Communicate with positioning tags and relay information back to the positioning engine algorithm software.

Positioning Engine Algorithm Software: Deployed on-premises, collects underlying data and processes it through positioning algorithms to obtain accurate coordinates of tags.

Positioning Application Software: Deployed on-premises or in the cloud, implements basic functions like positioning display and trajectory playback, as well as business functions extended from location data such as electronic fencing, intelligent inspection, attendance statistics, and video linkage.

III. System Hardware

IV. Solution Functions

Function Point | Function Description |

Real-time Personnel Positioning | Positioning accuracy of 0.3-1 meter, enabling real-time positioning management of substation maintenance personnel, viewing their real-time locations, distribution areas, etc., to grasp personnel dynamics anytime, anywhere. |

Historical Trajectory Query | Visual traceability of maintenance operations. By replaying historical trajectories, it organically combines spatiotemporal information with work content and video images. |

Personnel Roll Call | Can retrieve activity information of personnel within a specified area. |

Fall Detection for Elevated Work | For high-altitude and climbing work within the substation, checks if working conditions meet requirements. Electronic fences below the work area prohibit non-workers from walking or lingering. Checks for nearby overhead power lines or equipment, ensuring sufficient safe distance from live equipment is maintained. In some cases, power must be cut off before work. In case of slips or falls during high-altitude work, fall alarms are sent to the control center. Workers can also press the SOS alarm button to actively call for help.

|

One-Key SOS | The card has a built-in SOS button. Pressing for 3 seconds triggers audible and visual alarms on the system platform. |

Electronic Fencing | Sets virtual work fences based on maintenance tasks to supervise the work scope and duration of maintenance personnel. Links personnel tasks with time and space. Sets alarm fences for live operational areas during maintenance. If unauthorized personnel enter, alarm information is triggered on both the supervision platform and the tags worn by personnel. |

Inspection Management | Uses drawing tools to create circular, polygonal, or rectangular fence areas, configures basic area information, inspection plans, generates reports, etc. |

Area Personnel Statistics | Real-time statistics of personnel counts in various areas, e.g., switchgear room, GIS room, main transformer room, control room, outdoors, etc. |

Asset Positioning | Monitors fixed assets by attaching asset positioning tags. |

Alarm Record Information Management | Uses icon-based visual display for different types of alarm information. |

Data Statistics & Query | Displays statistical counts of alarms, provides query and printing of annual, monthly, and daily alarm statistics. |

Positioning Information Heatmap | Statistically analyzes personnel and vehicle distribution data on a positioning map, generating and displaying a heatmap. |

Location Tracking | Queries a snapshot of personnel positioning information distribution at a specific moment. |

Visitor Management System | Registers external personnel, allows adding, modifying, deleting, and handles card issuance and collection for visitors. |

Video Linkage | Integrates the UWB positioning system with the substation video surveillance system. Once an alarm occurs in an area (e.g., strangers at entrances/exits, personnel entering unauthorized areas, approaching hazards, SOS calls), the system immediately pops up live surveillance footage and takes photos to record the situation, providing basis for efficient decision-making. |

Hardware Status Management | Queries working status information of hardware like positioning base stations and beacons, displays their map locations for convenient future maintenance. |

Positioning System Supports Multiple Map Formats | Oblique photography, Hummingbird Cloud Map, Gaode Map, 3D modeling, 2D maps. |

V. On-site Photos

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier