I. Industry Status and Demand

A Smart Power Plant builds upon automation by leveraging IoT technology and equipment monitoring to enhance information management and services. It provides a clear grasp of the power generation process, increases process controllability, reduces manual intervention, and collects process data accurately and promptly. This enables the scientific formulation of generation plans and the construction of a humanized factory that is energy-efficient, environmentally friendly, and comfortable. By applying VR, big data, personnel positioning, and other technologies to the industrial field, the Smart Power Plant facilitates on-site monitoring, accident prediction, and diagnosis. It achieves a leap from digitalization to intellectualization, transforming traditional operation and management models and shifting from manual decision-making to machine-like decision-making.

The Smart Power Plant emphasizes both management and safety systems. Utilizing advanced technologies such as IoT, the Internet, and AI, it enables status monitoring and data collection at the equipment, control, and production supervision layers. This data is then fed into the central management core, achieving the ultimate goal of intelligent coordination in plant production. Current application demands and industry pain points for Smart Power Plants include:

Pain Point 1: The daily inspection management for personnel in production areas is relatively outdated. Traditional inspections rely on manual registration at checkpoints for recording and control. Inspection information cannot be shared in real-time within departments, and management cannot grasp the real-time status of inspections across various locations, leading to missed inspections.

Pain Point 2: The on-duty status of personnel in production areas cannot be quickly assessed. Traditional attendance methods, such as card swiping, are ineffective in supervising and statistically analyzing on-duty data and personnel distribution.

Pain Point 3: Power plants conduct planned unit maintenance, requiring a large number of external contractors for tasks like cleaning, excavation, and maintenance. There is a lack of effective means to supervise and statistically track the safety management and working hours of these external personnel, posing significant safety risks and data inaccuracies.

Pain Point 4: Current monitoring and management systems in power plants, such as video surveillance, personnel management, production management, and access control systems, operate relatively independently. Information exists in isolated silos, failing to provide emergency management platforms and comprehensive decision support for managers at all levels, resulting in low management efficiency.

Hainan Shidian addresses the application challenges and pain points of Smart Power Plants by introducing a solution based on UWB wireless positioning technology. This solution precisely locates personnel within the plant, ensuring their behavior is controllable and their positions visible. Combining positioning base stations, tags, and other equipment, it provides functions such as global location display, real-time trajectory tracking, historical data playback, and positioning monitoring analysis. It supports the rapid setup of electronic fences for accident-prone areas and issues local and remote warning alerts for personnel approaching or entering hazardous zones.

II. Overall Solution Architecture

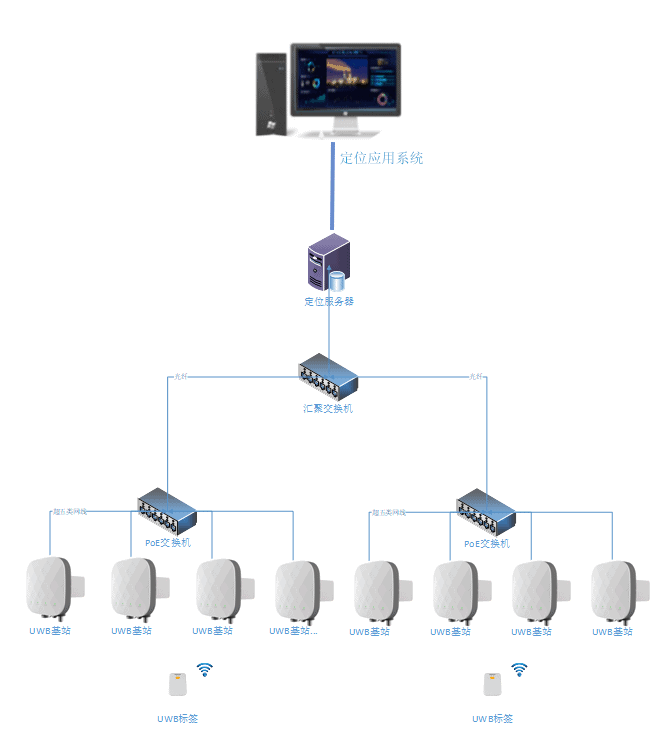

The system comprises UWB tags, UWB outdoor base stations, positioning engine software (C/S architecture), and a positioning application system. UWB tags and base stations communicate via UWB pulse signals. The base stations transmit received tag data via 5G networks or wired Ethernet to the LS1000 positioning engine for data analysis and processing. The processed precise location data is then transmitted to upper-layer applications through open API interfaces.

The system consists of the following:

- UWB Tags: Available in card-style and wristband-style, attached to personnel or assets. They periodically transmit UWB signals containing the tag ID.

- UWB Indoor Ceiling-Mount Base Stations: Communicate with positioning tags and relay information back to the positioning engine algorithm software.

- Positioning Engine Algorithm Software: Deployed on-premises, it collects underlying data and processes it through the positioning engine's algorithms to obtain the precise coordinates of the tags.

- Positioning Application Software: Can be deployed on-premises or in the cloud. This application-layer software implements basic functions like location display and trajectory playback, as well as business functions extended from location data, such as electronic fencing, intelligent inspection, attendance statistics, and video linkage.

Contact Us

III. System Hardware

UWB Base Station

IV. Solution Features

Feature | Description |

Real-time Personnel Positioning | Enables real-time positioning management for hydropower plant operators and inspection personnel. View real-time locations, distribution areas, and other information of personnel, keeping track of their movements anytime, anywhere. Positioning accuracy: 0.3~0.8 meters. |

Historical Trajectory Query | Provides visual traceability for maintenance operations. By replaying historical trajectories, it organically combines spatiotemporal information with work content and video footage. |

Personnel Roll Call | Can retrieve activity information for all on-duty personnel within a specified area. |

One-Key SOS | The card has a built-in SOS button. Pressing and holding for 3 seconds triggers audible and visual alarms on the system platform. |

Electronic Fencing | Sets virtual work perimeters based on maintenance tasks to supervise the work scope and duration of maintenance personnel. Links personnel tasks with time and space. Sets alarm fences for live operation areas during maintenance. Unauthorized entry triggers alarm information on the supervision platform. |

Inspection Management | Uses drawing tools to create circular, polygonal, or rectangular fence areas. Configures basic inspection area information, inspection plans, generates reports, etc. |

Alarm for Activity Outside Scheduled Time | Monitors the activity range of personnel wearing tags within a specified period. Alerts are issued if a person leaves the designated area for a certain duration. |

Alarm for Entry into Restricted Area | Restricts activity/access areas based on role type. Unauthorized entry triggers alarms. Passage conditions can be set for specific checkpoints; alarms sound for non-compliant personnel. Some areas may only be accessible during specific times; entry at other times is considered unauthorized intrusion and triggers an alarm. |

Loitering Alarm | Triggers an alarm if personnel do not leave an activity area within the stipulated time and remain for a certain period. |

Alarm Handling | For违规行为 (violations), the platform issues alarm information, causing the personnel's tag to vibrate continuously for active提醒 (reminder). Simultaneously, the platform pushes information to safety supervisors for on-site emergency response. For violations, real-time precise location information is used to关联调用 (associate and call) cameras for photo取证 (evidence collection). If on-site personnel encounter an accident requiring紧急救助 (emergency assistance), they can trigger the SOS button on the tag to send a distress signal to the platform. |

On-Duty Attendance | Automatically统计 (statistics) on-duty time, number of on-duty personnel, working hours, etc., for power plant operators, third-party personnel, and inspectors based on set attendance areas. Management can quickly query on-duty status. Monthly工时统计 (working hour statistics) can also directly参考 (reference) platform data for attendance review. |

Video Linkage | Integrates the UWB positioning system with the prison video surveillance system. Once an alarm occurs in an area (e.g.,陌生人出现 (stranger at entrance), unauthorized entry,接近危险源 (approaching hazard), SOS求救 (distress call)), the system immediately pops up the现场监控画面 (on-site camera feed) and拍照记录 (takes photos) of the situation, providing a basis for efficient decision-making. |

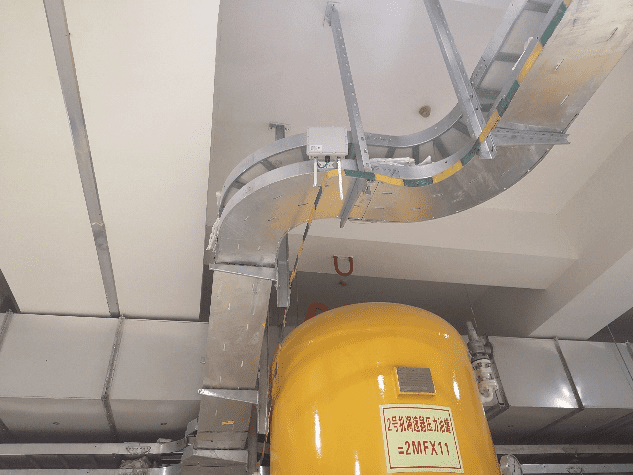

V. On-Site Installation Photos

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier