I: Overview

In recent years, China's economy has developed rapidly. As one of the main lifelines of global economic development, mining development provides a majority of the energy and industrial raw materials for economic growth. The mining mobile substation is the core equipment responsible for power transmission and distribution throughout the mine, determining the power source for all underground equipment. Underground electrical safety is a critical issue concerning the lives of miners. Therefore, the explosion-proof high and low voltage switches used for electrical safety control in mining mobile substations are particularly important. Their performance directly influences and determines the probability of safety incidents in the entire coal mine, making them crucial equipment that every coal mine carefully selects.

II: Industry Status and Needs

With the development of industrial automation and IoT application technologies, mining is also evolving towards intelligent mining, characterized by unattended operations, industrial robots replacing traditional miners, and remote large-screen monitoring. Intelligent mining technology will bring unprecedented opportunities to the global mining industry. Traditional mining technologies will gradually phase out, while intelligent, information-based, and automated mining technologies are about to open a new and vibrant field of technological development. In 2021, the National Energy Group and Huawei jointly released the MineHarmony operating system, providing systematic support for intelligent mining in China. Perhaps in the near future, mining coal with just a finger tap will no longer be a dream.

Although Huawei's MineHarmony system establishes a unified data standard (HCP) protocol, builds an industrial internet ecosystem, effectively breaks down "data silos" and "information chimneys" in coal mining enterprises, achieves data integration, sharing, and intelligent applications, and lays a solid foundation for intelligent coal mine construction, it also requires underground electrical and mechanical control equipment to have network communication access capabilities. Traditional power protection equipment, such as mining explosion-proof switches, typically only have RS485 communication interfaces commonly used in industrial communications, and cannot connect and communicate with the cloud server-based MineHarmony system. This poses obstacles and limitations to the development of smart mines and the promotion of MineHarmony. After communicating with a large mining equipment manufacturer to understand their pain points and challenges, Hainan Shidian successfully developed the RS485 to Ethernet/Fiber/WiFi Multi-function Networking Converter WE-KT700, targeting the industry networking application needs of mining mobile substation switches underground. This allows traditional mobile substation switches to instantly gain network interface communication capabilities, facilitating the integration of monitoring parameters from mining mobile substation switches into smart mine monitoring platforms like MineHarmony.

III: Product Introduction & Application Method

The WE-KT700 is an industrial-grade serial port RS485 network converter that simultaneously supports wired Ethernet, fiber optic, and wireless WiFi communication methods. It enables rapid networking of traditional serial devices through plug-and-play functionality.

- Supports three network communication methods: Ethernet, WiFi, and Fiber Optic

- Supports both AP and STA modes

- Supports 2 RS485 ports, with a maximum serial baud rate of 460800bps

- Supports multiple operating modes: Network Transparent Transmission; Modbus RTU to Modbus TCP; Modbus TCP to Modbus RTU

- Supports WiFi communication with a companion mobile APP (Modbus TCP)

- Supports firmware upgrades via serial port or network OTA

- Supports hardware Reset button for one-click factory default restoration

- Supports industrial-grade operating temperature: -40°C to +85°C

- Supports wide-range power supply: 5V to 36V

- Strict industrial reliability design, capable of withstanding 10KV arc interference

- Utilizes stable and reliable FC fiber optic connectors, supporting single-mode fiber up to 20km

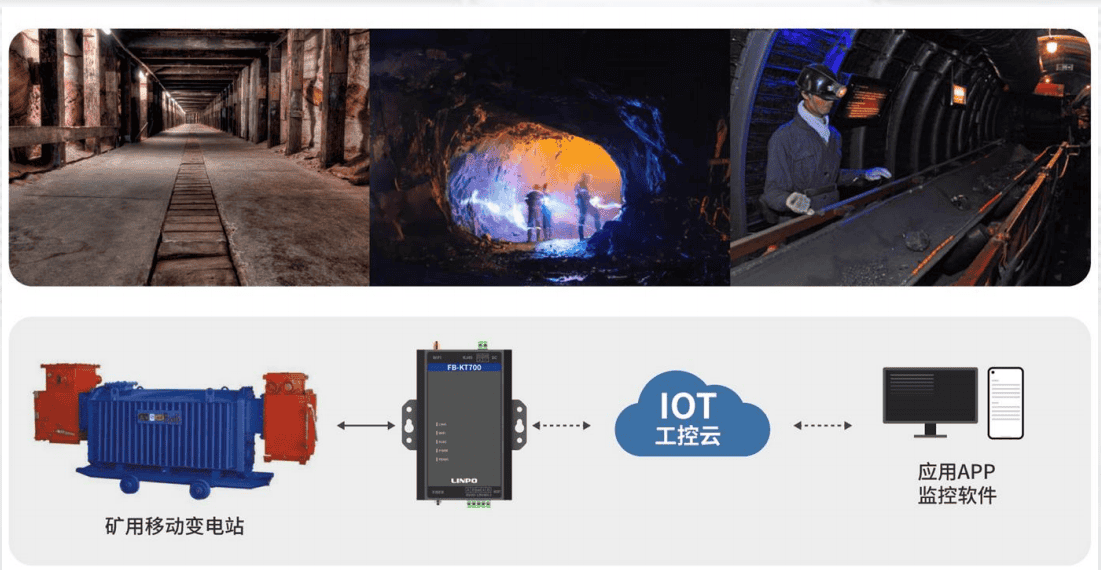

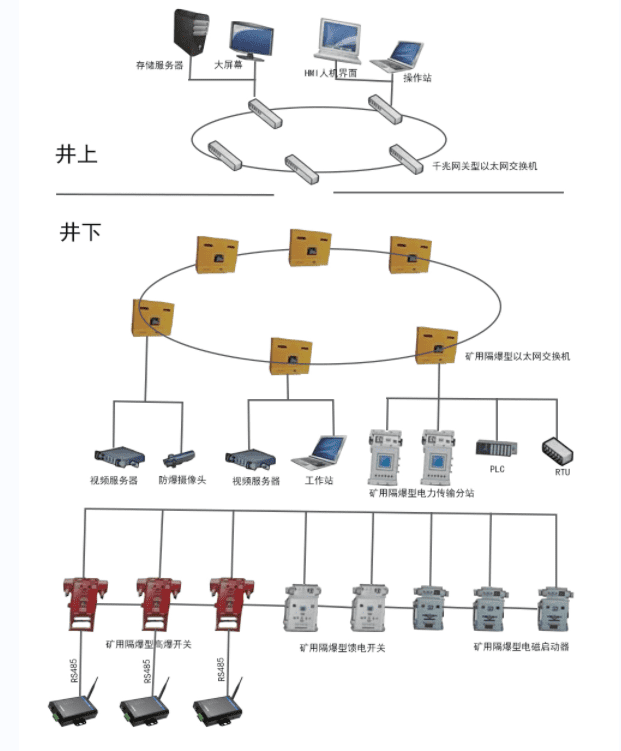

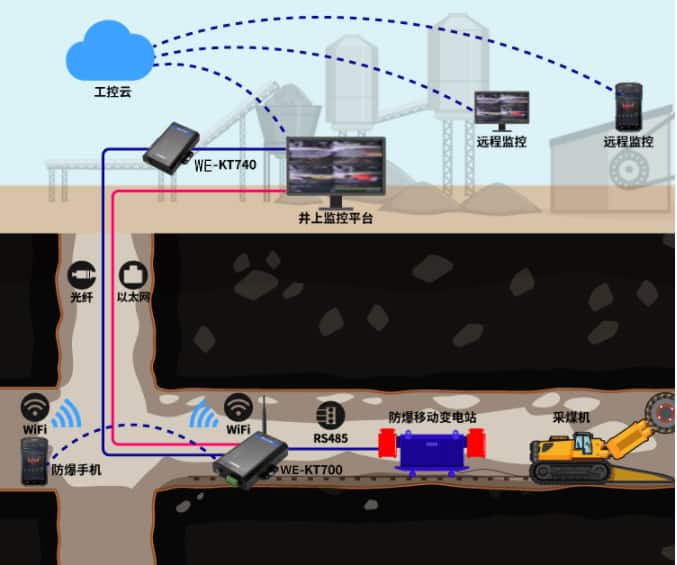

By adding an RS485 Tri-mode Converter WE-KT700 to each mining flameproof/explosion-proof high-voltage switch, the traditional flameproof switch becomes an intelligent high-voltage switch with network communication capability. The two communicate via the RS485 interface. Using any of the WE-KT700's network communication interfaces (Ethernet/Fiber/WiFi), the monitoring parameters of the high-voltage switch can be transmitted to the application server platform software on the surface, enabling timely monitoring of underground power conditions and safety. The application topology diagram of the entire system is as follows:

System Application Topology Diagram

Product Application Scenario Diagram

Product Physical Installation Diagram

Serial Server

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier