I. Solution Overview

Currently, China's manufacturing industry, despite its massive scale, suffers from extensive and non-detailed management. Although the government has advocated for "Smart Factories" and "Industry 4.0" for many years, the level of factory intelligence remains relatively low and cannot be compared with manufacturing powerhouses like Germany and Japan. Apart from some large enterprises such as Foxconn and Gree, which are actively experimenting with factory robots and automated management, the majority of small and medium-sized enterprises still survive relying on the comparative advantages of low labor costs and a relatively complete supply chain. With the rise of China's post-95s and post-00s generations, the new generation is no longer satisfied with the low-wage and overtime pay system. Coupled with the reflow and transfer of manufacturing to lower-cost countries like those in Southeast Asia, the difficulties faced by China's manufacturing industry have worsened. How can we change the management challenges of China's manufacturing factories and realize the transformation towards "Intelligent Factories" and "Smart Factories"? This is a common problem prevalent in China's manufacturing factories.

II. Challenges Faced by Factories

Due to the large number and dispersed nature of personnel in production workshops, it is impossible to monitor production line staff in real-time, quickly assess their on-duty status, and manage issues like unauthorized job switching or leaving posts. Currently, traditional manual supervision methods are ineffective in monitoring and statistically analyzing on-duty data. To better promote intelligent construction and achieve refined factory management, active ZigBee-based positioning technology is introduced to obtain the working hours invested by employees at various posts during the manufacturing process. Later, production capacity can be analyzed based on production reports to optimize the production structure and improve efficiency.

III. Solution Architecture

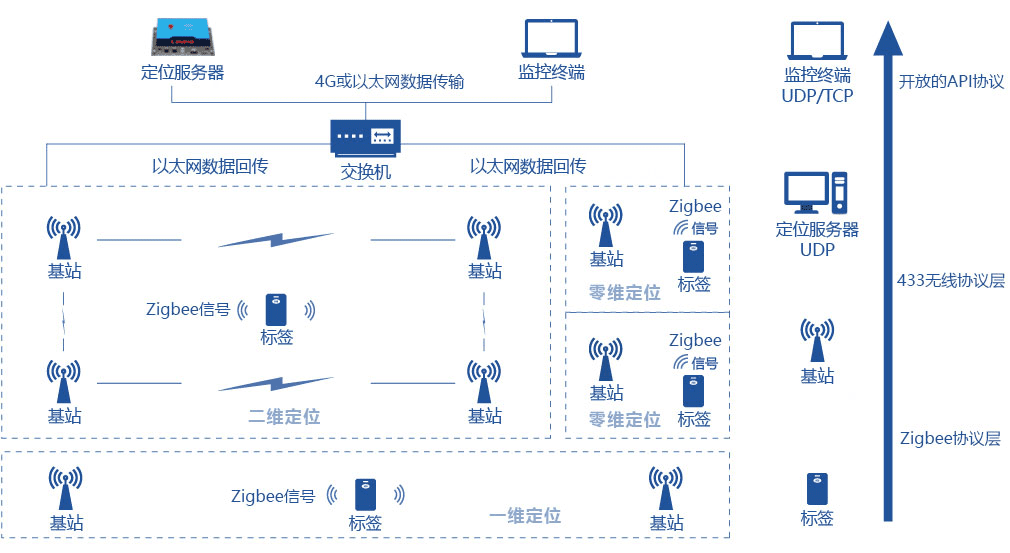

3.1 System Architecture

The factory personnel positioning system mainly consists of five parts: 1. Positioning tags carried by personnel; 2. Positioning base stations that receive information; 3. Network cables, DC power supplies, and switches for transmission and power supply; 4. Positioning location server; 5. Server computer and positioning software. Among them, the positioning tag is responsible for sending positioning pulse signals. The positioning base station receives the pulse signals and sends the information back to the location server via network cables and switches. The location server processes the positioning data and reports it to the positioning software on the server computer to display the positioning data in real-time.

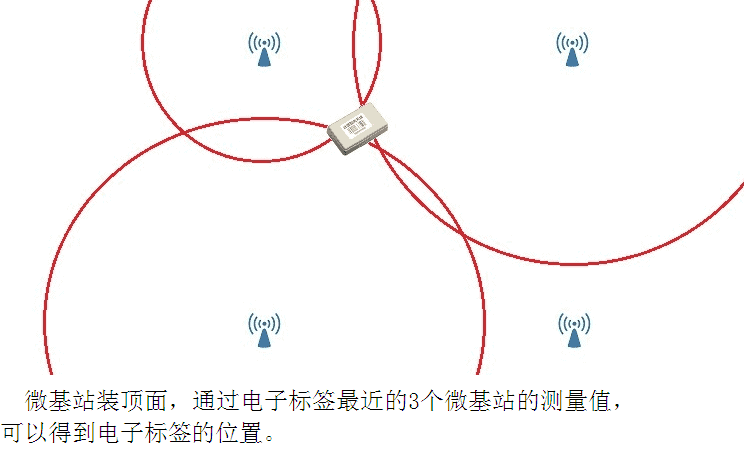

3.2 Trilateration Positioning Principle

3.3 Network Topology

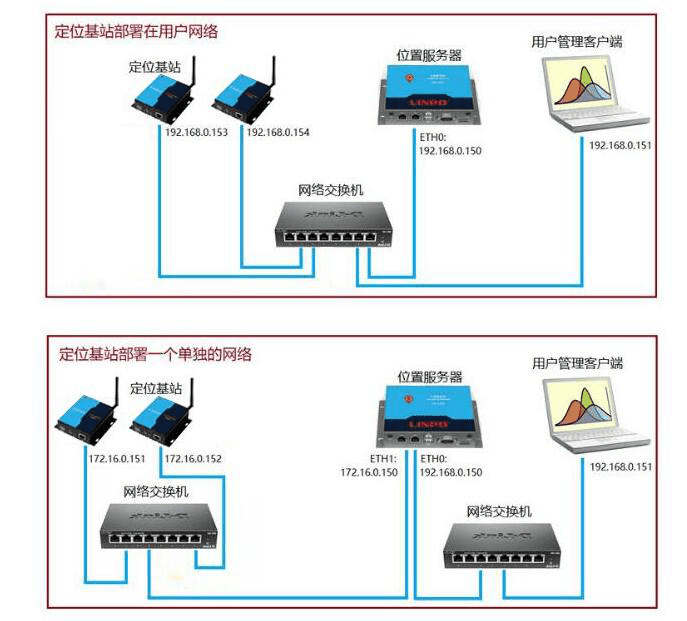

The 433MHz wireless network reader FB-RWN02 can expand up to 16 wireless readers via its wireless network interface, including itself (the device itself is also an independent reader), meaning a wireless network can have a maximum of 17 positioning base stations. The wireless readers report the read tag information to the network reader, which then reports all tag information within the wireless network range to the location server. The location server performs comprehensive calculations on the data to determine the specific location of the tags.

The location server has two Ethernet interfaces, ETH0/ETH1. If deploying positioning base stations within the user's network, only the ETH0 interface is needed. Alternatively, a new network can be built for the positioning base stations, in which case both Ethernet interfaces are used. It is recommended to build a new network for the positioning base stations so that the operation of the positioning system is not affected by the user's network, ensuring more stable operation.

IV. Requirement Implementation

4.1 Solution Product Portfolio

Electronic Tag 433MHz Wireless Reader WE-RW02¥730

Electronic Tag 433MHz Wireless Reader WE-RW02¥730 ZigBee Long-Range Semi-Active High-Precision Personnel Positioning Electronic Tag WE-T28K125¥60

ZigBee Long-Range Semi-Active High-Precision Personnel Positioning Electronic Tag WE-T28K125¥60 ZigBee 125K Semi-Active High-Precision Electronic Tag Low-Frequency Activator WE-TX125¥688

ZigBee 125K Semi-Active High-Precision Electronic Tag Low-Frequency Activator WE-TX125¥688 Badge WE-T32K Electronic Tag 2.4G Active RFID Card Ultra-Thin Waterproof Roll Call & Attendance¥38

Badge WE-T32K Electronic Tag 2.4G Active RFID Card Ultra-Thin Waterproof Roll Call & Attendance¥38 Long-Range Positioning Electronic Tag WE-T73¥66

Long-Range Positioning Electronic Tag WE-T73¥66 ZigBee Location Server WE-LS01¥4,339

ZigBee Location Server WE-LS01¥4,339 Active RFID 433 to Ethernet Network Reader WE-RWN02¥1,024

Active RFID 433 to Ethernet Network Reader WE-RWN02¥1,024 Electronic Tag 433MHz Wireless Reader WE-RW01¥730

Electronic Tag 433MHz Wireless Reader WE-RW01¥730 Long-Range Positioning Electronic Tag WE-T28¥42

Long-Range Positioning Electronic Tag WE-T28¥42 Item Positioning Replaceable Battery Electronic Tag WE-T22H¥52

Item Positioning Replaceable Battery Electronic Tag WE-T22H¥52

4.2 Tag Management

Tags are distributed and bound according to the real-name system, one tag per person. Before issuing cards, tags need to be bound to designated workers on the platform, and personnel information, job content, etc., need to be entered.

When tags are recycled, the associated information needs to be unbound on the platform. For personnel in specific positions who use tags long-term, this operation may not be necessary.

V. System Functions

1. Real-time Monitoring of Factory Workers to Solve Difficulties in Workshop Patrols

By distributing electronic tag cards to workers to locate their real-time positions within the factory workshops, management personnel can view the real-time locations of different types of personnel in the system backend, facilitating supervisors in understanding the real-time status of personnel in different workshops and areas at any time.

2. Unconscious Automatic Clock-In to Solve Difficulties in Worker Attendance

Each day when a worker first enters the factory building, their location and time are automatically recorded, generating an attendance record in the backend. This truly achieves unconscious automatic attendance.

3. Stationary Alarm for Workers to Solve Laziness Issues

The electronic tags worn by workers detect if a worker remains stationary in a certain location. When the stationary time exceeds the preset range, a stationary alarm is automatically sent to the employee's supervisor to prevent worker laziness.

4. Hazardous Area Alerts to Solve Accident-Prone Issues in Factory Hazardous Areas

The Shidian Technology personnel positioning system features a customizable virtual fence area setting function. Once the virtual electronic fence is set up, an alarm is immediately sent to the backend system when a worker enters the electronic fence, allowing factory management to promptly know who has entered the factory's hazardous areas.

VI. System Features and Advantages

- Positioning Accuracy: Average accuracy of 3-5m;

- Longer Coverage Range: Line-of-sight coverage distance of 30-100m;

- More Flexible Networking Methods: Stable wired network;

- Free Client Software for managing tags, positioning base stations, and viewing real-time tag locations.

- Open Management Protocol, allowing complete integration of positioning functions into your own system platform.

- Outward Transmission of UDP Location Data, facilitating system integration. Supports deep custom development.

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier