I. Industry Status and Demand

A cement plant's production line consists of a series of equipment for manufacturing cement, primarily comprising processes such as crushing and pre-homogenization, raw meal preparation and homogenization, preheating and decomposition, clinker burning, and cement grinding and packaging. During the cement production process, at least 3 tons of materials (including various raw materials, fuel, clinker, mixtures, and gypsum) need to be ground for every ton of Portland cement produced. Statistics show that grinding operations in dry-process cement production lines consume over 60% of the plant's total power, with raw meal grinding accounting for over 30%, coal grinding for about 3%, and cement grinding for about 40%. This cement plant faces the following application pain points in its production management process:

Pain Point 1: Cement production and petrochemical enterprises belong to high-risk industries characterized by high temperature, high pressure, flammability, explosiveness, and toxicity. Coupled with features such as large-scale, dense production facilities, complex production processes, and tightly coupled production stages, they pose greater hazards compared to discrete manufacturing. Moreover, process manufacturing involves numerous production equipment and workers; once an accident occurs, it can lead to immeasurable losses. Therefore, how to strengthen control and reduce the probability of hazardous incidents has always been a challenge for modern process manufacturing. Traditionally, production safety management personnel relied on retrieving video surveillance footage to locate personnel and ensure the safety of production workers. This approach may suffer from blind spots, control gaps, and the inability of supervisors to constantly monitor multiple camera feeds.

Demand 1: To ensure the production safety of personnel in process manufacturing and improve management levels, integrate advanced positioning technology with traditional control methods for operational management. This enhances control coverage, eliminates blind spots, and allows multi-department managers to remotely access on-site personnel information and status.

Pain Point 2: In situations where on-site personnel production operations and external personnel control are not strict, the complex on-site environment can lead to workers mistakenly entering hazardous areas, resulting in accidents. Control room managers need to constantly watch large-screen video monitors, and on-site operation supervision also requires assigning safety inspectors. When multiple areas have simultaneous operational tasks, significant manpower is consumed for monitoring, and accidents may still occur due to oversight.

Demand 2: To improve the efficiency of operational supervision, utilize advanced positioning technology for operational control, implementing electronic fencing and alarm location functions. Compared to the traditional method where dedicated personnel were assigned to monitor video feeds of hazardous areas to ensure worker safety—which also carried the risk of managerial negligence leading to danger and safety incidents—the introduction of advanced positioning technology addresses and mitigates the safety risks posed by on-site construction personnel accidentally entering prohibited areas during production. Once unauthorized personnel intrude, an alarm is generated on the on-site personnel management platform. Control room managers can be immediately notified and can inform on-site security to investigate. The tags worn by on-site and field personnel will immediately vibrate to alert them, ensuring management convenience and on-site personnel safety.

Pain Point 3: On-site inspection personnel ensure the normal operation of the factory by promptly identifying potential hazards and dangerous situations related to equipment and the site, thereby resolving and eliminating issues to maintain orderly factory operations. Inspection personnel should conduct operational checks at various locations throughout the plant's sections on time and as required. With the current traditional on-site inspection method, most involve inspection personnel manually signing, registering inspection times, and recording data. This leads to issues with timeliness and the possibility of personnel substituting for each other during inspections.

Demand 3: By incorporating positioning technology to achieve inspection management functions, integrate traditional inspection methods with personnel positioning. On-site inspection managers can pre-set various inspection points within the factory and define sequences for different points, making on-site inspections smarter and more convenient. This system verifies whether inspection personnel complete their rounds on time, addressing and optimizing the timeliness of inspection management while ensuring the accuracy of the personnel conducting the inspections.

II. Overall Solution Architecture

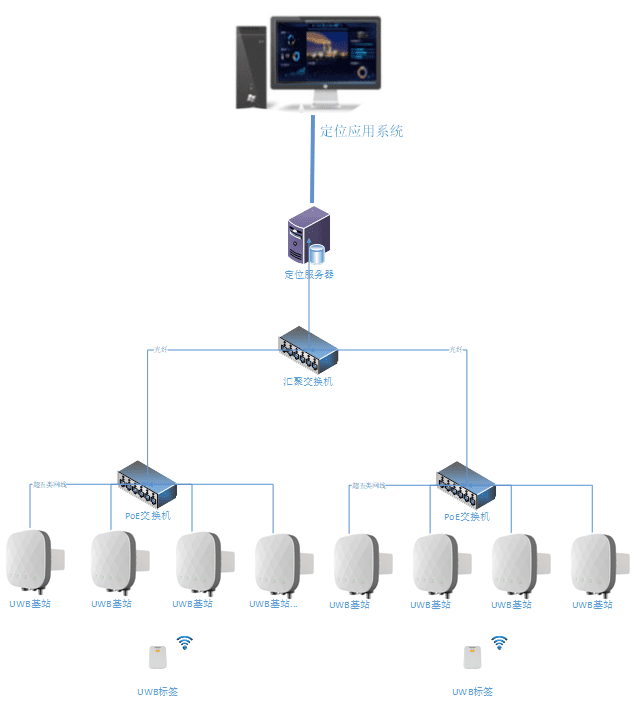

The system includes UWB tags, UWB outdoor wired base stations, positioning engine software (C/S architecture), and a positioning application system. Positioning tags and base stations communicate via UWB pulse signals. The base stations transmit received tag data via 5G network or wired Ethernet to the LS1000 positioning engine for data analysis and processing. The processed precise location data is then transmitted to upper-layer applications through open API interfaces.

The system composition is as follows:

- UWB Tags: Available in card-style and wristband-style, attached to personnel or assets. They periodically transmit UWB signals containing the tag ID information.

- UWB Outdoor Wired Base Stations: Communicate with positioning tags and relay information back to the positioning engine algorithm software.

- Positioning Engine Algorithm Software: Deployed on-premises. It collects underlying data and processes it through the positioning engine's algorithms to obtain the precise coordinates of the tags.

- Positioning Application Software: Can be deployed on-premises or in the cloud. This application-layer software implements basic functions such as location display and trajectory playback, as well as business functions extended from location data, including electronic fencing, intelligent inspection, attendance statistics, and video linkage.

III. On-site Deployment

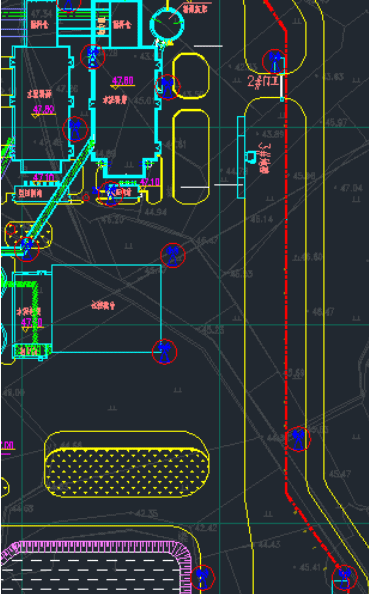

Based on the factory areas requiring coverage at this cement plant, combined with drawings and on-site surveys, a feasible base station deployment plan was evaluated, as shown in the diagram below:

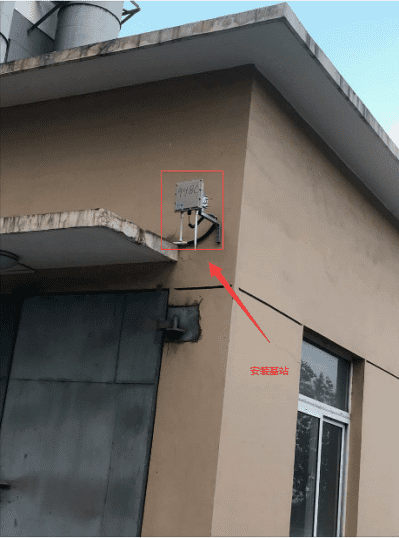

After the plan was reviewed and approved by relevant parties, the construction phase commenced (handled by the integrator for installation, with guidance from Hainan Shidian for installation and debugging). Base stations were installed at designated locations according to the design plan. Photos of the actual installation are shown below:

Positioning Application Platform Software Showcase

The platform software can provide real-time statistics on the number of people in various areas, such as the limestone crushing workshop, cement grinding workshop, waste heat power generation plant, central control room, outdoor cement dispatch yard, etc. It constructs a visual, integrated, intelligent, and three-dimensional digital intelligent management and control platform, improving the comprehensive management efficiency of safety production within the plant. Personnel safety management efficiency has been increased by over 20%.

UWB Base Station

Content Reviewer:

Professional IoT solution equipment supplier

Professional IoT solution equipment supplier